In modern industrial manufacturing, with increasing demands for welding quality, efficiency, and consistency, orbital tube welding machines have become critical equipment for stainless steel pipe welding. This is particularly true in high-standard industries such as pharmaceuticals, bioengineering, semiconductors, food and beverages, the nuclear industry, and aerospace, where weld joints require exceptionally high levels of seamlessness, cleanliness, and repeatability, which traditional manual welding methods struggle to meet. Orbital welding machines, with their high precision, high automation, and programmability, have become the mainstream choice in the orbital pipe welder market.

So, among the numerous brands and models available, how do you choose an orbital welding machine that offers stable performance, a high cost-effectiveness, and the right fit for your process needs? This article will provide a professional purchasing guide covering core technical specifications, application scenarios, user needs analysis, after-sales service guarantees, and budget assessment to help you make an informed decision.

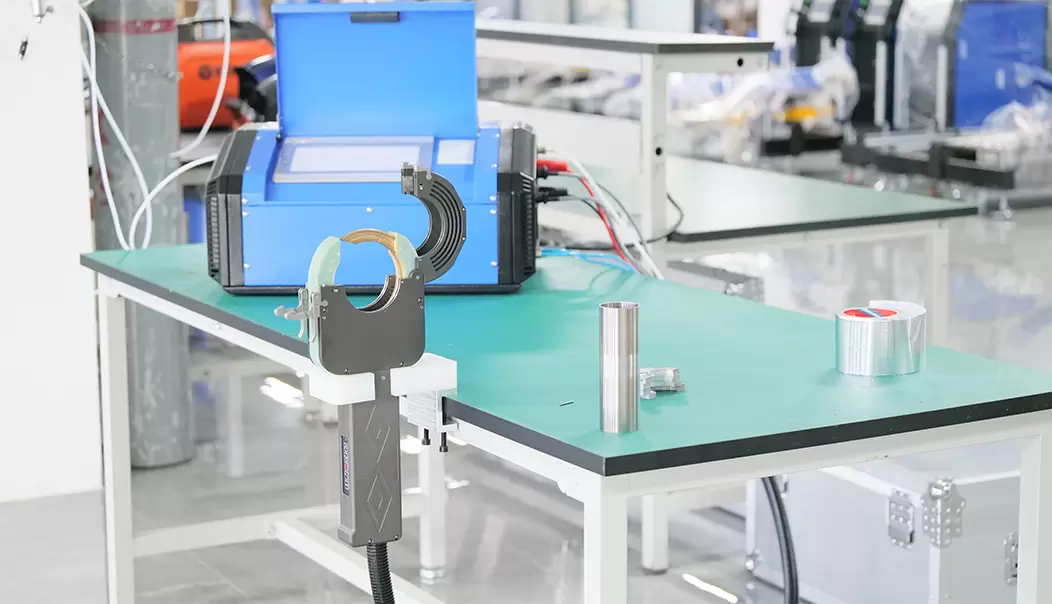

An orbital welding machine is an automated welding system designed specifically for butt welding of pipes and fittings. The welding torch orbits the pipe in a 360° motion, achieving seamless welds.

1.1 Principle Analysis

Orbital welding primarily uses the TIG (Tungsten Inert Gas Arc) welding method. During the welding process, the electrode remains stationary while the welding torch moves in a circular motion along the pipe. The system controls parameters such as wire feed speed, current, voltage, and argon shielding time to create a stable weld pool and achieve highly consistent welding results.

1.2 Core Advantages

High Weld Consistency: Effectively avoids problems such as uneven welds, slag inclusions, and porosity that can occur during manual welding.

High Cleanliness: No spatter and a small heat-affected zone make it ideal for materials sensitive to heat distortion, such as stainless steel.

High Efficiency: Significantly reduces welding time, especially in batch welding.

Easy to Operate: Operators can easily master the process after simple training, reducing reliance on skilled technicians.

Programmable Control: Multiple welding programs can be stored to accommodate a wide range of workpiece sizes.

To ensure that the selected equipment meets your production needs, the following key parameters should not be overlooked:

2.1 Pipe Diameter Range

Different models of orbital welding machines have different pipe diameter ranges. For example, some small orbital tube welders are suitable for pipes ranging from 6mm to 38mm in diameter, while industrial-grade equipment can handle pipes up to 200mm in diameter or even larger.

2.2 Welding Thickness Capability

Confirm the minimum and maximum wall thickness ranges supported by the equipment. Pharmaceutical and food-grade pipes typically have thin walls, while chemical and nuclear power pipelines tend to have thicker walls, resulting in significant differences in requirements.

2.3 Power Supply and Welding Current Control

High-quality orbital welding machines are typically equipped with a digitally controlled power supply that supports multi-stage current/pulse current adjustment to accommodate different materials and working conditions.

2.4 Welding Head Structure and Cooling System

When purchasing, consider whether to choose an air-cooled, liquid-cooled, or enclosed welding head for more stable gas shielding based on the working environment.

2.5 Automation

Advanced orbital pipe welders support automatic parameter setting, welding process monitoring, data storage, and remote fault diagnosis, greatly enhancing operator convenience.

2.6 Operational Convenience and Portability

In practice, orbital welding machines are often used for on-site installation. Therefore, its size, weight, and modular design are also noteworthy. Portable orbital tube welding machines are more suitable for small-batch, distributed pipeline projects.

2.7 Brand and After-Sales Service

A high-quality brand signifies more mature technology, more comprehensive technical support, and more stable equipment performance. We recommend prioritizing:

Manufacturers with a good reputation in the industry;

Service providers that provide installation guidance, operating training, and long-term technical support;

Brands with long warranties and readily available spare parts.

Clarify your actual welding requirements and develop a reasonable list of technical specifications;

Based on brand strength and user reputation, prioritize suppliers with mature technology and comprehensive after-sales service;

Inspect the equipment's operating status and customer feedback on-site;

Request the manufacturer to provide detailed equipment specifications, welding samples, and technical training support.

4. Common Purchasing Misconceptions

Misconception 1: Focusing solely on price and ignoring performance

Some users focus solely on the low price of the equipment, ignoring the performance and stability of the welding machine. This results in substandard welding quality and increased rework costs. Misconception 2: Blindly Pursuing High-End Configurations

Some companies choose overly complex equipment for the sake of appearing "high-end" or "advanced," but they may not actually use all of its features in production, resulting in complex operation and high costs. A thorough assessment of your production line's needs and choosing the right configuration is the most economical and practical solution.

Misconception 3: Neglecting Operation Training and Personnel Compatibility

Although orbital welding machines are automated, they still require professional training and skilled operation to achieve optimal results. Failure to consider personnel training and operational difficulty during procurement can easily lead to equipment being left idle or misused.

Misconception 4: Disregarding After-Sales Service

Equipment failures or commissioning issues are inevitable. If a supplier's after-sales response is slow or technical support is insufficient, production lines can be severely impacted. Before purchasing, thoroughly investigate the supplier's service network and technical response speed to ensure stable equipment operation.

With the accelerating pace of industrial automation, orbital welding technology is constantly upgrading, with intelligent, refined, and traceable processes becoming the trend. Choosing the right efficient and stable orbital welding machine is not only a key step in improving product quality but also a key sign of a company's progress towards intelligent manufacturing. If you are looking for a high-quality, highly automated orbital pipe welder that meets international standards, please contact us. We are a professional orbital welding machine supplier and will provide you with personalized welding solutions and technical support to help you fully upgrade your production process.