In modern industrial production, especially in high-standard cleanroom industries like pharmaceuticals, food and beverages, semiconductors, and aerospace, the quality of stainless steel pipe connections is directly related to the stability and safety of the entire system. To ensure consistent, clean, aesthetically pleasing welds with excellent strength, more and more companies are turning to orbital welding machines as their preferred equipment for stainless steel pipe welding.

Orbital welding machines are technologically advanced, expensive to purchase, and require strong adaptability to specific applications. Therefore, selecting a reliable orbital welding machine manufacturer is crucial for achieving efficient and high-quality welding. So, with so many brands and manufacturers on the market, how should companies choose? This article will analyze the key criteria and considerations for selecting an orbital welding machine manufacturer from multiple perspectives.

Before selecting a manufacturer, it's important to first clarify your true needs. Orbital welding machines are widely used because of their advantages:

The welding process is fully or semi-automated, saving time and effort.

Weld seam consistency is excellent, making them suitable for applications requiring the highest aesthetics and strength.

They offer minimal contamination risk, making them suitable for cleanroom applications.

They are suitable for thin-walled stainless steel pipes, avoiding burn-throughs and cold welds.

Stainless steel pipe welding, in particular, requires high precision in terms of pipe diameter, wall thickness, material, and positional accuracy, making it difficult for manual welding to meet quality standards. Therefore, the use of orbital welding machines for such applications is almost a necessity.

Before purchasing, companies are advised to conduct a self-assessment of the following technical parameters:

Pipe diameter range (e.g., Φ6mm to Φ168mm)

Wall thickness range

Material type (304, 316L, titanium alloy, etc.)

Weld seam type (pipe-to-pipe, pipe-to-elbow, flange, etc.)

Batch welding requirements or custom welding tasks

Requirement of advanced features such as a cooling system, data logging, and programmable welding parameters

These prerequisites will determine the type of orbital welding machine you choose and also provide criteria for subsequent manufacturer selection.

2.1 Technical Strength and R&D Capabilities

High-quality orbital welding machine manufacturers typically have strong R&D teams and the ability to continuously improve their equipment. You can identify these manufacturers based on the following:

Whether they have an independent core software control system

Whether they possess independent R&D expertise for core components such as welding heads, cooling systems, and controllers

Whether they have ongoing patents or product upgrades in the orbital welding field

Whether they support customized development solutions

These manufacturers can often provide you with stable, continuously upgradeable welding solutions, not just a single piece of equipment.

2.2 Equipment Compatibility and Process Coverage

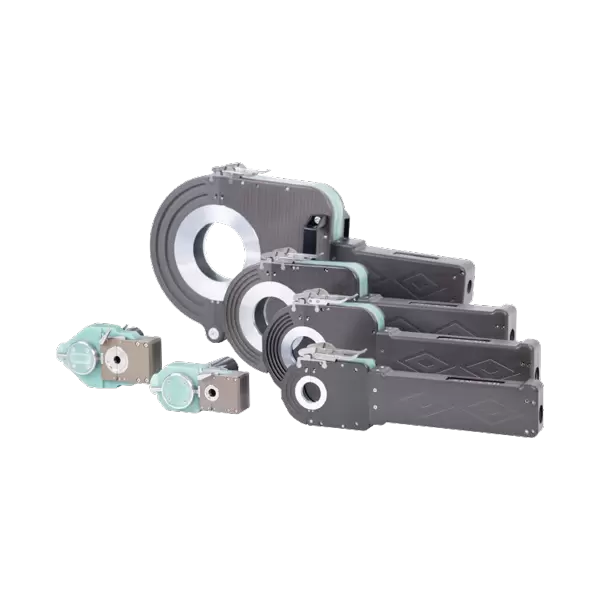

There are many types of orbital welding machines on the market, such as closed-loop welding heads, open-loop welding heads, and automatic wire feed systems. A good manufacturer can offer:

A variety of welding head models to suit different workpieces

Support for welding of various pipe diameters and wall thicknesses

Compatibility with a wide range of metal materials, especially stainless steel

Support for programmable welding parameter settings for batch operation

If a manufacturer only offers a single model with a single function, future expansion capabilities will be significantly limited. 2.3 Welding Quality and Case Verification

Any reliable orbital welding machine manufacturer should be willing to provide real customer cases and welding samples for your reference. Consider the following:

Is the weld smooth, free of pores and burn-through?

Is consistent weld quality achieved across multiple batches?

Is actual weld measurement data (tensile strength, penetration, X-ray, etc.) available?

Are there any known applications in well-known companies or projects (e.g., food and pharmaceutical factories)?

Real cases are the most direct way to verify equipment performance and the manufacturer's capabilities.

2.4 After-Sales Service and Technical Support

Welding equipment is high-precision equipment. Failures can potentially halt production. Therefore, excellent after-sales service is crucial.

Does it offer equipment commissioning and on-site installation services?

Does it provide operator training and welding process guidance?

Is the fault response time clear (e.g., within 24 hours)?

Does it maintain a regular spare parts inventory, and what are the repair cycles?

Some manufacturers promise lifetime technical support, remote parameter adjustment, and regular follow-up visits; these can serve as evaluation criteria. 2.5 Cost-Effectiveness

While price is important, it should never be the sole criterion. We recommend that companies consider the following from a comprehensive "total cost" perspective:

Initial equipment purchase price

Maintenance costs and frequency of replacement of consumable parts

Failure rate and downtime costs

Rework costs due to poor weld pass rates

Truly valuable equipment often saves companies significant labor and wear and tear during use.

2.6 Corporate Reputation and Industry Influence

A manufacturer's market reputation can be assessed through the following methods:

Has it obtained ISO, CE, or other quality system certifications?

Has it received industry awards or received government scientific and technological support?

Are customer reviews positive?

Has it participated in industry exhibitions or technical exchange forums?

Brand and reputation may not be everything, but they often reflect a manufacturer's long-term commitment to quality.

3. Practical Tips: How to Verify a Manufacturer's Reliability Here are some practical tips:

Investigate the production workshop and R&D capabilities on-site

Request a free sample welding trial or demonstration

Compare solutions, quotes, and technical services from two to three manufacturers

Learn about the manufacturer's equipment usage from peer companies

An orbital welding machine is more than just a piece of equipment; it's a complex industrial system. A quality manufacturer not only provides the equipment but also offers one-stop welding process support, training services, spare parts supply, and after-sales service.

Faced with the dazzling array of orbital welding machine brands and manufacturers on the market, only by comprehensively considering multiple factors—technology, quality, service, case studies, reputation, and price—can companies avoid detours and move forward steadily on the path to welding automation.

As a professional orbital welding equipment manufacturer, we specialize in the research and development and manufacturing of automated stainless steel pipe welding solutions, dedicated to providing high-precision, highly consistent welding equipment for high-purity industries such as pharmaceuticals, food, semiconductors, and nuclear power. We possess proprietary control systems and a variety of welding heads suitable for various pipe diameters and materials, supporting customized solutions. With consistent welding quality, comprehensive after-sales service, and extensive industry application experience, we have earned the trust of numerous customers and are your reliable orbital welding partner.