Exhibition Dates: September 23-27, 2025

Exhibition Location: National Exhibition and Convention Center (Shanghai)

NODHA Booth Number: 7.1H--E016

Exhibits:

Agile Welding Carriage

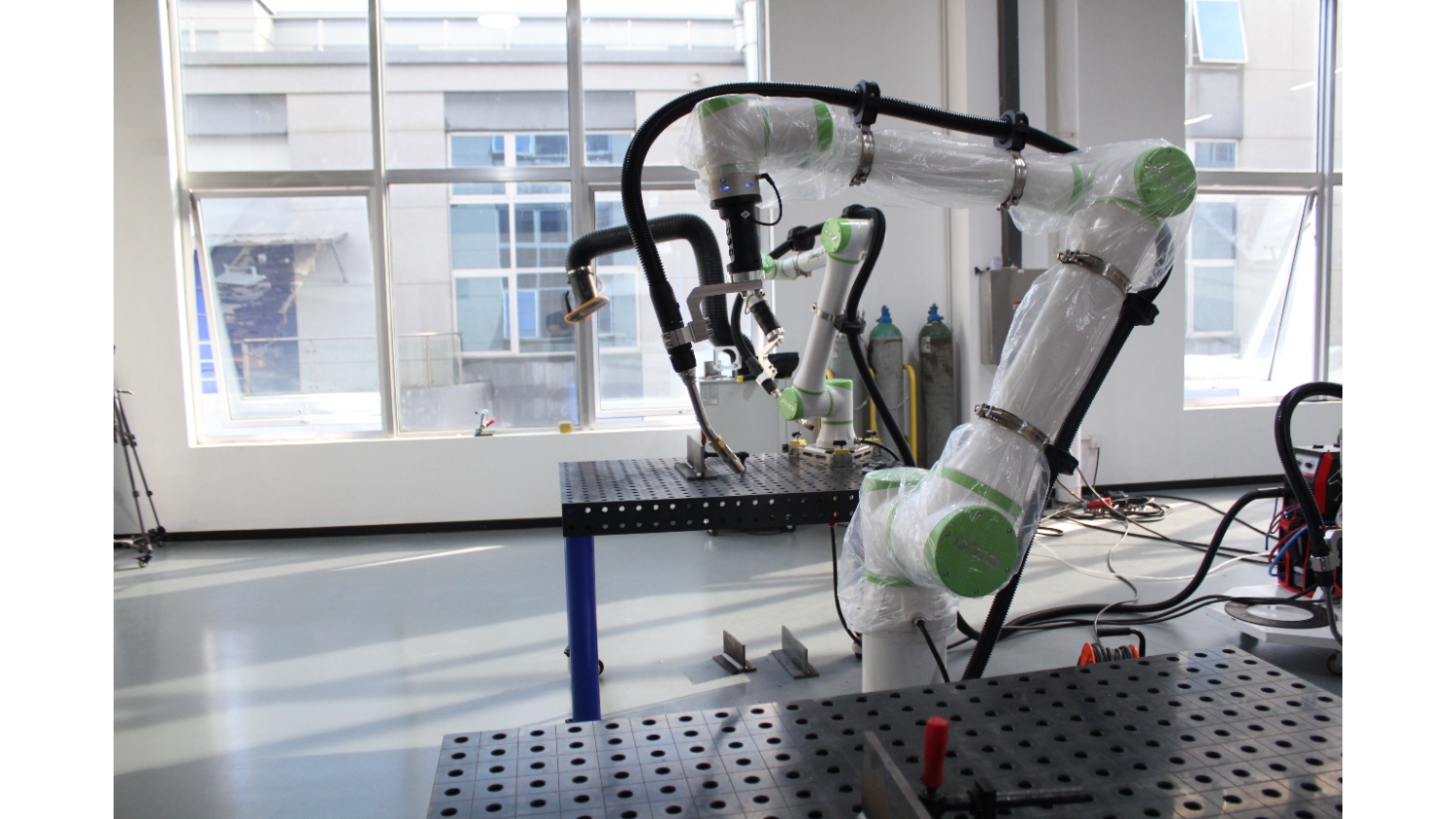

1. The welding robot arm utilizes the IATF 1699 automotive-grade certified Changguangxi Intelligent Manufacturing Robot Arm—a flexible robot body with higher repeatability, faster speed, and greater rigidity. The robot arm's damping settings enable easy drag-and-drop programming.

2. Highly integrated, flexible deployment, human-machine collaboration, and efficient operation make it the ideal choice for small-batch, high-variety welding. It can weld small workpieces or attach the robot arm to large workpieces via a magnetic base.

3. The welding software supports both basic and advanced processes, including arc swinging, multi-pass, arc tracking, and wire tracking, meeting a wide range of welding requirements.

Eight-Axis and Nine-Axis Linkage Dual-Station Workstation

1. Dual-Station Welding Workstation: A servo-based floor rail coordinates the robot to perform scheduled alternating welding operations at two stations. This supports a "clamping-welding-disassembly" production process, enabling cyclic welding. The "dual-station + floor rail" design reduces non-welding time by 70%, significantly improving production efficiency.

2. Ten-Axis Linkage Based on EtherCAT Communication Protocol: The robot exchanges data with four servo drives via EtherCAT in real time, achieving microsecond response speeds. This simplifies the system architecture, improves communication efficiency and control accuracy, and enables precise ten-axis control of the robot, positioner, and floor rail to achieve the optimal welding position. This significantly expands the robot's effective workspace and enables welding of complex trajectories.

3. Mobile Arc Welding Cart: This system combines the ease of use and flexibility of collaborative robots, enabling drag-and-drop welding to lower the barrier to entry. By integrating into a mobile welding workstation, it allows for easy and flexible deployment, making it suitable for flexible production scenarios involving small batches and a wide variety of products. Welding processes can be called and edited via a tablet, achieving the advantage of "weld-and-use" functionality.