In modern manufacturing, stainless steel welding is a key process, widely used in industries such as food, pharmaceuticals, chemicals, semiconductors, and construction. With increasing production demands, traditional manual welding can no longer meet the high efficiency, precision, and consistency required. Automated orbital welding machines have emerged, revolutionizing the stainless steel welding process. This article will analyze in detail how automated orbital welding machines improve stainless steel welding processes from multiple perspectives, helping procurement personnel and technical engineers understand their advantages and application value.

1.1 High-Precision Welding

Stainless steel welding requires extremely high weld quality, especially in food-grade piping and pharmaceutical equipment. Welds must be smooth, free of holes and spatter. Traditional manual welding is easily affected by operator experience and the environment, resulting in inconsistent weld quality.

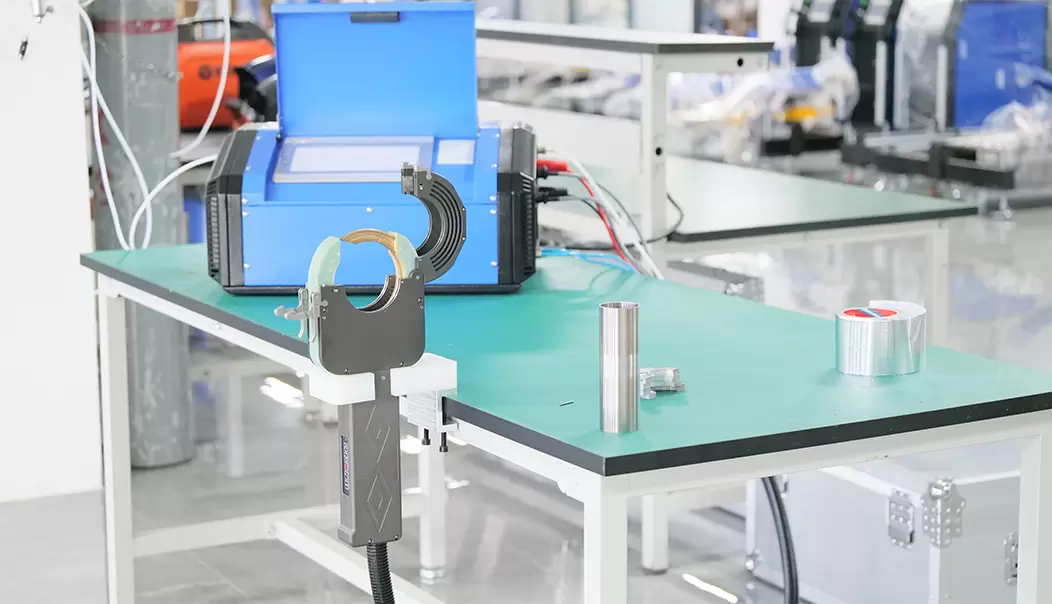

Automated orbital welding machines utilize track guidance and a precise control system to move the welding head along a fixed track, ensuring consistent depth, width, and speed for each weld, significantly improving welding accuracy and product quality. This precision is particularly important in stainless steel welding, as weld defects can directly impact corrosion resistance and aesthetics. 1.2 Improved Production Efficiency

Traditional welding is limited by manual operation, resulting in low efficiency and long cycle times. However, orbital welding machines enable continuous operation and high-speed welding.

Automated orbital welding machines not only reduce manual intervention but also enable multi-point continuous welding through program control. The efficiency gains are particularly significant for large-scale production projects. For example, in the production of large-scale food processing or pharmaceutical pipelines, the use of orbital welding machines can reduce welding cycles by 30% to 50%, significantly increasing overall production capacity.

1.3 Reduced Operational Difficulty

Stainless steel welding requires high skill levels, and manual welding requires experienced welders. Automated orbital welding machines, on the other hand, are simple to operate and rely almost entirely on operator skill. Simply set welding parameters such as current, voltage, welding speed, and gas flow, and the equipment automatically completes the welding process, significantly reducing manual errors and training costs.

2.1 Intelligent Process Parameter Control

Automated orbital welding machines automatically adjust welding current, voltage, and welding speed based on stainless steel pipe thickness, weld joint type, and weld length. This intelligent control ensures consistent process parameters for each weld, achieving standardized welding quality across mass production. In addition, some high-end orbital welding machines are equipped with data acquisition and storage capabilities, which can record welding process parameters for later analysis and quality traceability, improving production management.

2.2 Reduced Rework and Material Waste

Because automated orbital welding machines maintain weld consistency, they are less likely to produce porosity, weld depressions, or uneven welds, significantly reducing rework. Furthermore, precise control of weld volume reduces excess welding material consumption, thereby lowering production costs.

3.1 Food and Pharmaceutical Industries

Food-grade and pharmaceutical equipment require extremely high weld hygiene standards, requiring smooth and contamination-free welds. Automated orbital welding machines achieve high-precision welding while ensuring a smooth stainless steel surface finish that fully meets hygienic standards, making them a valuable choice for modern food, beverage, and pharmaceutical equipment production.

3.2 Semiconductor and Electronics Industries

Semiconductor production pipelines and high-purity gas systems require welds free of trace contamination. Using orbital welding machines eliminates the impurities and uneven welds that can occur with manual operation, improving production yields. 3.3 Construction and Large-Scale Engineering Equipment

Welding large stainless steel structures presents long welds and significant welding challenges. Orbital welding machines enable long-distance, stable welding, improving overall structural strength and safety.

Identify welding requirements: Select an appropriate automated orbital welding machine model based on welding materials, pipe diameter, and industry standards.

Focus on equipment configuration: This includes welding power supply performance, control system intelligence, welding head accuracy, and cooling system.

Evaluate after-sales service: High-quality manufacturers provide technical training, maintenance support, and consumables, ensuring long-term, stable operation.

Price/Performance Ratio and Budget: Imported brands are recommended for high-end industries, while domestically produced high-end models can be selected for cost-effective industries to balance cost and performance.

With the development of Industry 4.0 and smart manufacturing, application trends for automated orbital welding machines include:

Intelligence and Networking: Welding equipment can enable remote monitoring, data analysis, and process optimization.

Multifunctional Integration: Welding, cutting, grinding, and other processes can be integrated into a single production line to improve overall efficiency. Customized Solutions: We provide tailored welding solutions tailored to specific materials, pipe diameters, or industry requirements.

In the future, automated orbital welding machines will play an even more important role in stainless steel welding processes, creating higher production value for businesses.

Utilizing high-precision control, intelligent parameter adjustment, and a stable rail guidance system, automated orbital welding machines have revolutionized stainless steel welding, achieving consistent welding quality, improved efficiency, simplified operation, and standardized processes. For the food, pharmaceutical, semiconductor, and large-scale engineering sectors, automated orbital welding machines not only improve production efficiency but also reduce long-term maintenance costs, becoming a crucial tool for upgrading modern welding processes.

With the advancement of industrial automation, orbital welding machines will be widely adopted in more industries, bringing higher production efficiency and guaranteed welding quality.

As a professional automated orbital welding machine manufacturer, NODHA is committed to providing high-precision and high-efficiency stainless steel welding solutions to customers across various industries. Leveraging advanced rail guidance technology and intelligent control systems, NODHA's equipment significantly improves welding accuracy, stability, and production efficiency, and is widely used in sectors with stringent welding quality requirements, such as food, pharmaceutical, semiconductor, and rail transportation. At the same time, the company provides comprehensive after-sales service and technical support to help customers optimize welding processes and reduce production costs. It is a trustworthy partner for many companies.