With the rapid development of the semiconductor industry, from wafer manufacturing to packaging and testing, the requirements for precision, cleanliness, and reliability of production equipment are becoming increasingly stringent. Against this backdrop, the precision and consistency of the welding process have become a critical aspect of semiconductor equipment manufacturing. Traditional manual welding methods are prone to uneven weld seams, spatter, or contamination under high-precision requirements. Orbital welding machines, with their automation, high precision, and repeatability, are being widely used in the semiconductor industry, becoming an important tool for improving equipment quality and production efficiency.

Semiconductor production equipment is characterized by high precision, high cleanliness, and complex structures, which places stringent requirements on the welding process:

High-Precision Welding: The numerous stainless steel, aluminum alloy, and special alloy parts used in semiconductor equipment require extremely high weld seam precision. Weld seam deviations or unevenness directly affect the mechanical and packaging precision of the equipment.

Clean Environment Requirements: Spatter, slag, or gas contamination generated during the welding process can impact the semiconductor production environment. Therefore, welding equipment must be able to complete welding under controlled contamination conditions.

Complex Structure Welding: Semiconductor manufacturing equipment contains numerous precision pipes, valves, tanks, and irregularly shaped parts. The welding process must ensure structural integrity and sealing.

Repeatability and Stability: In mass production, every weld must maintain consistency to ensure reliable equipment function and ease of maintenance.

Traditional manual welding struggles to meet these requirements, especially in high-precision welds, clean environments, and complex structure welding. This highlights the advantages of automated track welding machines.

In the semiconductor industry, products are tiny and structurally precise, demanding extremely high welding quality. Compared to traditional manual welding and fixed welding equipment, track welding machines offer significant advantages:

High-Precision Welding: Semiconductor packaging often involves connecting tiny components such as metal leads, chip supports, and heat sinks. Track welding machines, through precision guide rails and CNC systems, achieve micron-level positioning accuracy, ensuring weld consistency.

Automation and High Efficiency: Track welding machines enable unmanned operation, completing continuous welding through program control, significantly improving production efficiency. For high-volume semiconductor packaging production lines, this reduces labor costs and minimizes human error.

Minimal Heat Impact: Orbital welding machines using lasers or electron beams concentrate the heat source, significantly reducing the thermal impact on surrounding sensitive components and preventing chip damage or material deformation—a critical requirement in the semiconductor industry.

Traceability and Quality Monitoring: Orbital welding machines record parameters for each weld, including power, speed, time, and trajectory. Combined with a vision inspection system, welding data traceability is achieved, improving product quality management.

Diverse Process Adaptability: Orbital welding machines can adapt to welding requirements for different materials (such as copper, aluminum, tungsten, etc.), thicknesses, and structures, meeting the diverse requirements of chip packaging, power device welding, and heat sink welding in the semiconductor industry.

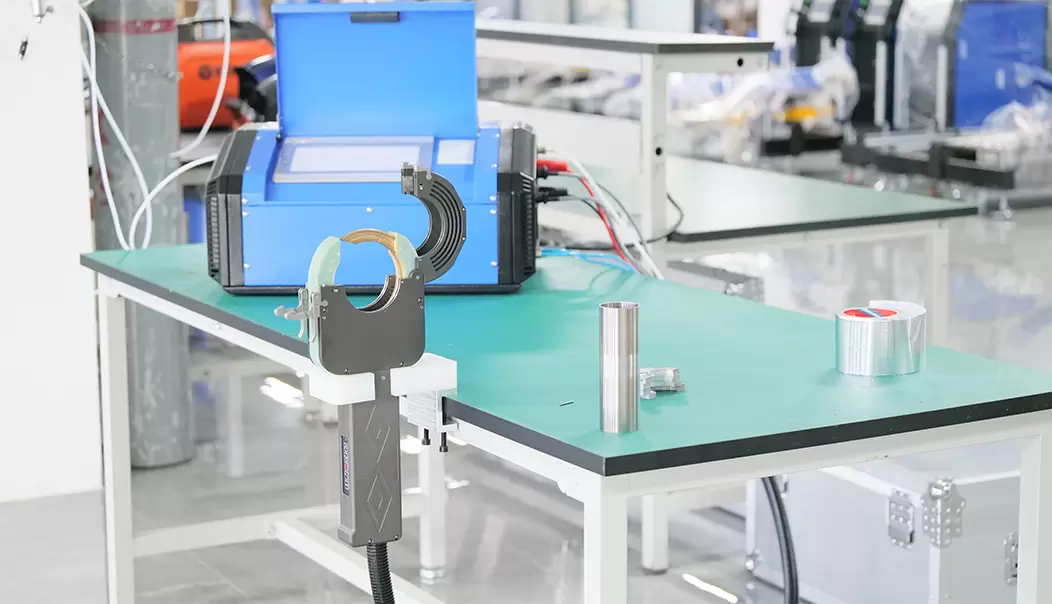

3.1 Stainless Steel Pipe Welding: In semiconductor production, clean pipes are used to transport gases, liquids, or chemicals. Stainless steel pipes have small diameters and thin walls, requiring smooth, leak-free welds. Orbital welding machines can automatically move the welding torch along the pipe axis, achieving precise welding of straight or circular welds, significantly improving welding efficiency and weld quality.

3.2 Vacuum Chamber Welding: Vacuum chambers in semiconductor equipment require high sealing performance. Traditional manual welding is prone to micro-cracks or pores, while track welding machines can precisely control welding speed and current, achieving porosity-free, uniform welds and ensuring the cavity remains in a vacuum state for extended periods.

3.3 Precision Component Welding

Semiconductor equipment includes precision stainless steel components such as valves, reactors, and sensor housings. These components have complex dimensions and are highly sensitive to weld smoothness and heat-affected zones. Track welding machines, through programmable control systems, can flexibly adjust welding paths, angles, and welding parameters to achieve high-precision welding of complex geometries.

Despite the significant advantages of track welding machines, their application in the semiconductor industry also faces certain challenges:

High equipment cost: The integration of high-precision track systems, laser welding heads, and closed-loop monitoring systems results in substantial investment for track welding machines, potentially posing a barrier to entry for small businesses.

Complex welding parameter optimization: Different materials, thicknesses, and packaging structures require fine-tuning of welding power, speed, and trajectory, leading to lengthy parameter optimization cycles.

High environmental requirements: The semiconductor industry has extremely high cleanliness requirements. Track welding machines must operate in a dust-free environment; otherwise, welding defects or chip surface contamination may occur.

Professional Maintenance and Operation Requirements: Due to the high precision of orbital welding machines, maintenance and operation personnel must possess professional skills; otherwise, the equipment's lifespan and welding quality may be affected.

Orbital welding machines, with their advantages of high precision, high efficiency, low heat impact, and automation, play an increasingly important role in chip packaging, power device welding, thermal management, and micro-device welding in the semiconductor industry.

For semiconductor manufacturing companies, the appropriate introduction of orbital welding machines can not only improve production efficiency and product quality but also lay a solid foundation for future high-precision packaging and high-end chip manufacturing.

NODHA, as a professional orbital welding machine distributor, is committed to providing efficient and reliable automated welding solutions for the semiconductor, food processing, chemical, and high-precision manufacturing industries. The company not only provides advanced orbital welding machine equipment but also offers one-stop services including equipment selection, installation and commissioning, operation training, and after-sales maintenance, ensuring customers achieve high-precision welding, stable efficiency, and high-quality weld results in their production processes. With rich industry experience and professional technical support, NODHA has become a trusted partner for many companies in the field of rail welding.