In the field of modern industrial manufacturing, orbital cutting machines, as an efficient and precise cutting equipment, are widely used in the automated cutting process of materials such as pipes and metals. It not only improves production efficiency, but also greatly improves cutting quality, meeting the needs of high-precision manufacturing. However, there are many brands of orbital cutting machines on the market, and the quality and service vary. How to choose a reliable orbital cutting machine manufacturer has become an important issue for purchasers and enterprises.

This article will analyze the key factors for choosing a reliable orbital cutting machine factory from multiple angles to help you efficiently select a trustworthy orbital cutting machine partner.

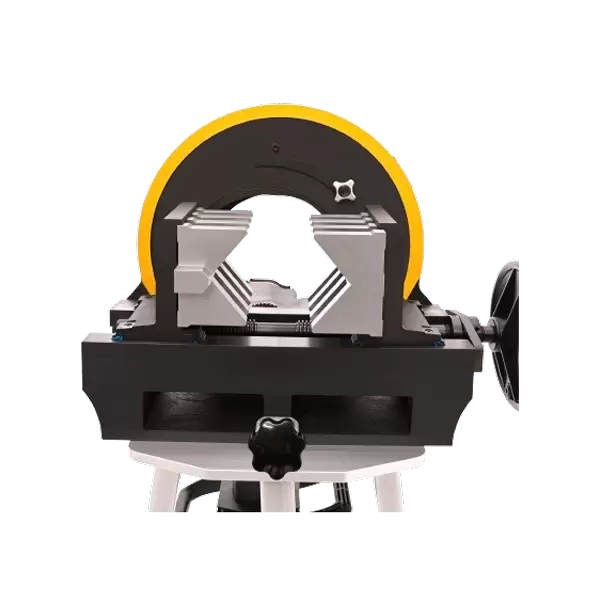

Before choosing a manufacturer, you must first have a basic understanding of the technical characteristics and application scope of orbital cutting machines. orbital cutting machines are suitable for precision cutting of pipes and are commonly used in industries such as petrochemicals, shipbuilding, aerospace, and automobile manufacturing.

The advantages of orbital cutting machines include:

High-precision cutting: rail guides ensure that the cutting path is accurate and without deviation;

High degree of automation: save manpower and improve production efficiency;

Stable cutting quality: reduce burrs and deformation, and reduce secondary processing costs;

Diverse applicable materials: can cut carbon steel, stainless steel, aluminum alloy and plastic pipes, etc.

High-quality orbital cutting machine manufacturers usually have strong R&D and manufacturing capabilities, and can provide technologically advanced and stable products. Several important indicators for evaluating the technical strength of manufacturers:

Ask the manufacturer whether it has an independent R&D team;

Whether it regularly launches new products or technology upgrades;

Whether it has patented technology to ensure product uniqueness and competitiveness.

Whether the manufacturer's production equipment is advanced and can guarantee product accuracy and stability;

Whether it uses advanced processes such as CNC machining and laser welding;

Whether the production process is standardized and whether it has ISO9001 quality management system certification.

Whether to provide prototype trials or on-site demonstrations;

Whether the product performance has been tested by an authoritative organization or verified by customers;

Whether detailed technical information, test reports and use cases can be provided.

As key equipment, the quality of orbital cutting machines directly affects production efficiency and product qualification rate. When choosing, you should focus on:

Key components such as rail guides and cutting heads are made of high-strength and wear-resistant materials;

Whether the motor and control system use internationally renowned brand components to ensure service life and stability.

Whether the body structure is stable to reduce the impact of vibration on cutting accuracy;

Whether the rail design ensures smooth movement and avoids jamming;

Whether the operation interface is user-friendly and convenient for adjustment and maintenance.

The warranty period and after-sales service commitment provided by the manufacturer;

Whether the equipment is suitable for long-term continuous operation;

Whether there are protective measures to ensure the safety of the equipment.

Reliable manufacturers not only have excellent product quality, but more importantly, they have perfect pre-sales, in-sales and after-sales services to help customers use the orbital cutting machine smoothly.

Whether the manufacturer can provide personalized solution design according to customer needs;

Whether to provide free technical consultation and selection guidance;

Whether there is a professional engineer team to support on-site commissioning and training.

Are the warranty scope and period clear?

Whether timely equipment maintenance and troubleshooting services are provided?

Whether the spare parts supply is sufficient and convenient.

Is there regular user training to help customers master equipment operation skills?

Whether software upgrades and technical transformation are supported to maintain the advanced nature of the equipment.

The manufacturer's market reputation and customer success cases are important references for judging its strength and reputation.

Understand the user experience and service evaluation through online evaluations, industry forums or direct interviews with existing customers;

Pay attention to the efficiency of the manufacturer in handling customer complaints and after-sales problems.

Whether the manufacturer has been focusing on the field of orbital cutting machines for many years?

Whether it has rich industry solutions and customization experience?

Whether there are cases of cooperation with well-known companies to verify its strength and reputation.

Price is an important factor in purchasing decisions, but low price cannot be used as a selection criterion alone. When choosing a orbital cutting machine, you should consider the cost-effectiveness comprehensively:

Whether the product performance and quality match the price;

Whether the after-sales service is included in the price to avoid subsequent additional costs;

Maintenance costs and failure rates for long-term use.

The products of high-quality orbital cutting machine manufacturers are reasonably priced and transparent, which can bring real cost-effectiveness to customers.

As an important equipment for industrial automation, it is particularly important to choose a reliable manufacturer for orbital cutting machines. The above comprehensively analyzes the key standards for selecting orbital cutting machine factories from the aspects of technology, quality, service, reputation, price, etc. I hope this article can help you avoid purchasing misunderstandings, find high-quality orbital cutting machines that suit your production needs, and help enterprises achieve more efficient and accurate manufacturing upgrades.