Home > Application > Plate Machinning Equipment > GDM-265D Double-Sided Slag Removal Machine Operation Case

Home > Application > Plate Machinning Equipment > GDM-265D Double-Sided Slag Removal Machine Operation Case

Efficiently and smoothly cleaning welding slag and rust from unprocessed steel plate workpieces has always been a challenging process in the manufacturing industry. Traditional manual grinding is not only labor-intensive and inefficient, but also easily damages the surface of the base material, affecting the final appearance and corrosion resistance of the product. In the factory workshop of NODHA strategic partner GIRET, to better demonstrate the machine's double-sided slag removal function, technicians operated the GDM-265D automatic double-sided slag removal machine, showcasing the GDM-265D double-sided slag removal solution to the customer with its superb "one-shot" processing performance.

I. Challenge: The Efficiency and Quality Dilemmas of Traditional Processes

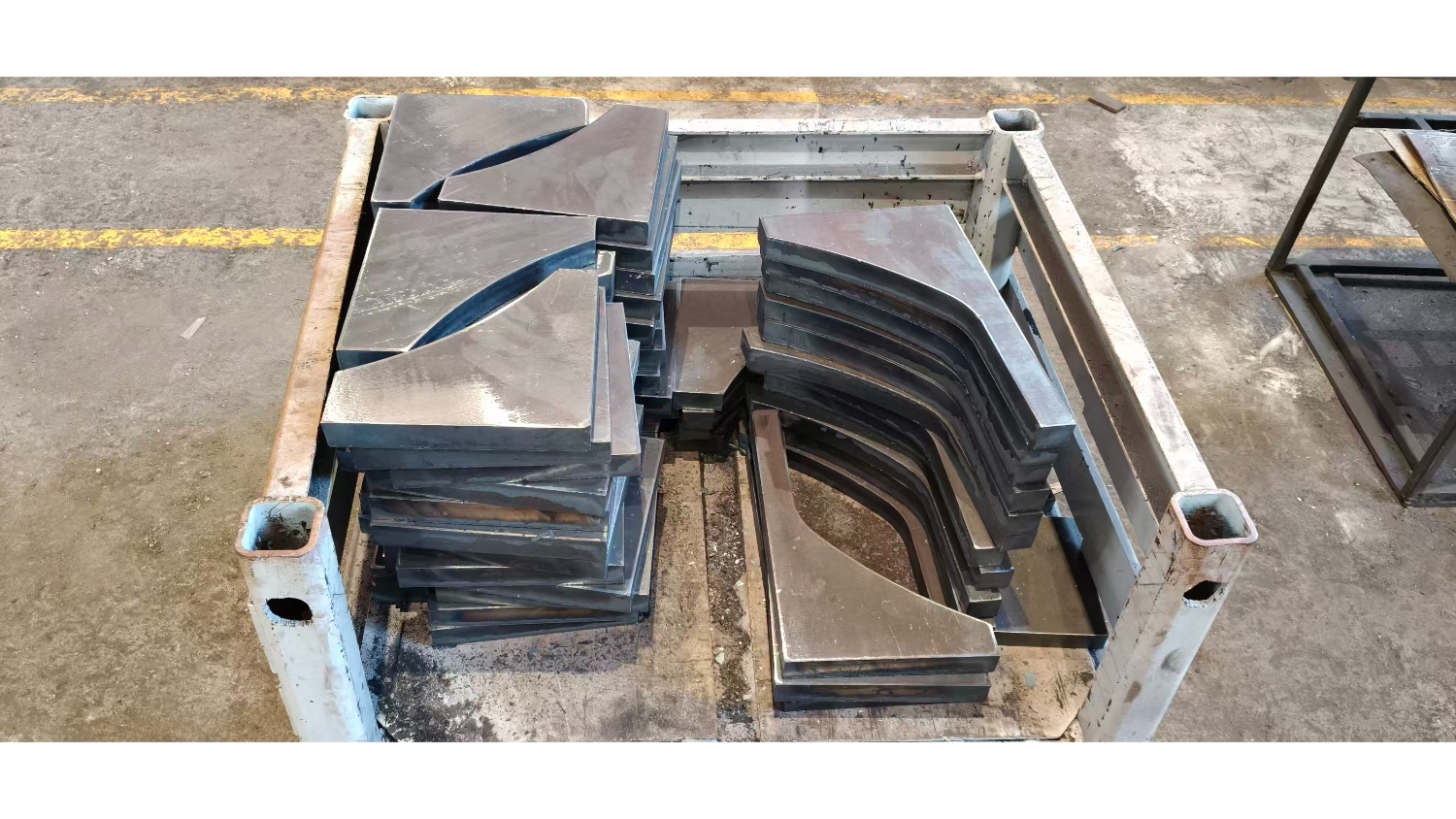

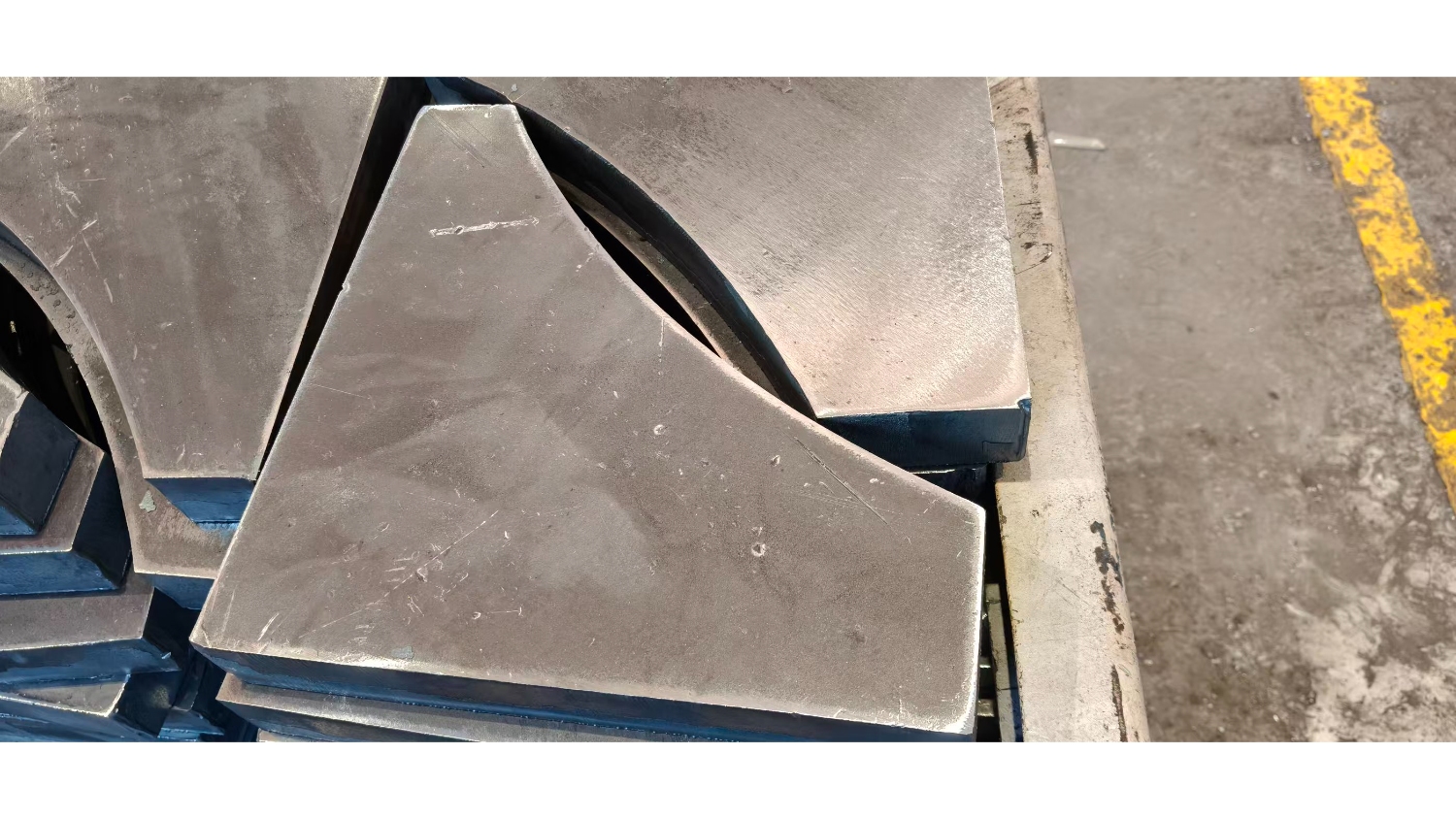

Before the demonstration began, several unprocessed steel plate parts were placed on site, their front and back sides covered with rough and uneven welding slag and oxide scale. Traditional angle grinders, when used manually, require a skilled worker to frequently flip workpieces weighing tens of kilograms and grind both sides separately. This process is not only time-consuming (up to ten minutes), but also fails to ensure even pressure, easily leaving scratches of varying depths on the base material surface, affecting coating adhesion, and causing severe dust pollution.

II. Innovation: Double-sided grinding completed in a single feed, with no dust pollution

GIRET technicians hoist the workpiece onto the feed roller conveyor of the GDM-265D. With the equipment started, the entire processing process is clear and smooth:

Continuous feeding, stable and efficient: Driven by the powered roller conveyor, the workpiece smoothly passes through the processing area of the equipment at a constant speed, without interruption or flipping, achieving truly continuous operation.

Single feed, synchronous processing: This is the core advantage of the GDM-265D. When the workpiece passes through the "processing gateway" composed of two sets of independent powered grinding heads, the two sets of high-strength grinding discs start simultaneously, acting on both sides of the workpiece at once, precisely milling away the protruding weld slag in the weld area.

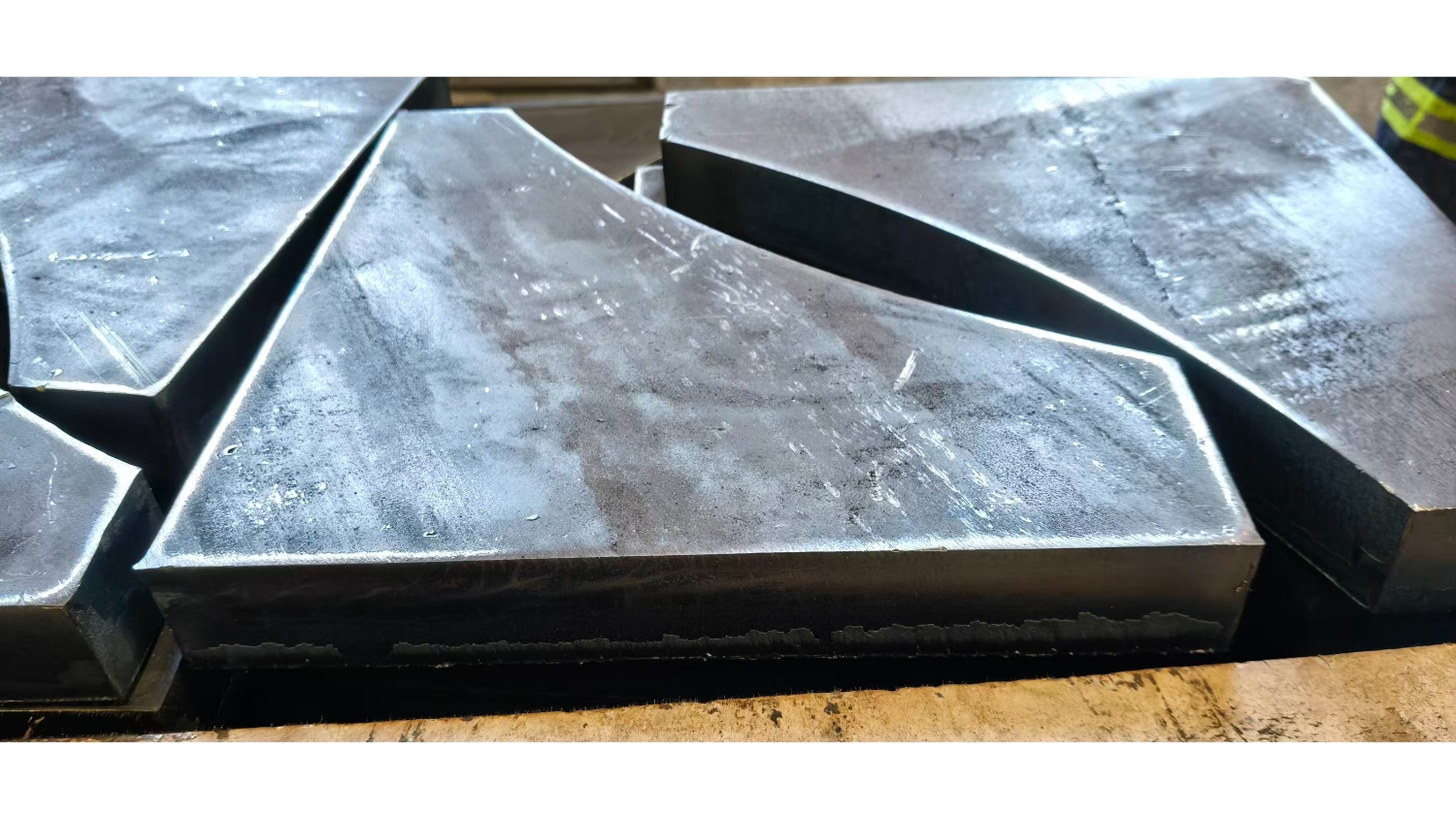

Precise Control, Protecting the Base Material: The equipment utilizes a precise gap adjustment system to ensure the grinding disc only acts on the raised weld slag areas requiring cleaning, achieving "zero-contact" protection for the smooth surface of the base material. This fundamentally avoids accidental wear and damage caused by traditional grinding.

III. Results: A Leap in Efficiency and Quality

The entire processing is completed in a single, streamlined process within minutes. The difference is striking when the workpiece exits the discharge end:

Surface Quality: The previously rough weld area becomes smooth and flat, with the original metallic color evenly revealed.

Efficiency Comparison: The GDM-265D completes double-sided slag removal of the same workpiece in less than one-tenth the time of traditional manual methods, significantly improving efficiency.

Comprehensive Advantages: In addition to the leap in efficiency and quality, this process greatly reduces reliance on highly skilled workers, achieves clean production with the help of a dust collection system, and significantly extends the life of consumables by avoiding over-grinding.

IV. Power Parameters of GDM-265D Automatic Slag Removal Machine

Grinding Motor: 3750W * 2

Feed Motor: 750W

Compressor Motor: 400W

Air Pressure: 0.5 MPa

Fan Airflow: 2 * 25 m³/min

Power Supply: AC380V 50Hz

V. Technical Parameters of GDM-265D Automatic Double-Sided Suspended Slag Removal Machine

Plate Width: 650 mm

Plate Thickness: 9~60 mm

Plate Length: >170 mm

Workbench Height: 900 mm

Workbench Dimensions: 675 * 1900 mm (Total Length of Workbench)

Slag Removal Speed: Feeding Speed: 2~4.0 m/min; Slag removal can be completed on both sides with a single feed.

Net Weight: 2200 kg