Home > Application > Orbital Cutting & Welding > Efficiently complete the cutting, beveling, and welding of Ø50.8×2.9 stainless steel pipes

Home > Application > Orbital Cutting & Welding > Efficiently complete the cutting, beveling, and welding of Ø50.8×2.9 stainless steel pipes In the production operation area of NODHA's new factory, the entire process of cutting, beveling, and welding pipes with a diameter of 50.8 mm and a wall thickness of 2.9 mm was carried out. The entire process was independently operated by NODHA technicians using core equipment from the Orbital Cutting & Welding series—a planetary pipe cutter, a pipe beveling machine, and a BH80 welding machine. The fast, efficient, safe, and convenient operation fully demonstrated the technical advantages and practical value of the series.

I. Project Background and Task Requirements

Stainless steel pipes (Ø50.8×2.9 mm) were processed in multiple steps, including precision cutting, end beveling, and girth welding.

The NODHA technical team's processing solution:

Planetary pipe cutting machine: achieves high-precision cold cutting;

Pipe beveling machine: completes end beveling;

BH80 automatic pipe welding system: equipped with a P200 power supply and an automatic gas shield module, performs welding and forming.

II. Equipment Configuration and Processing Process

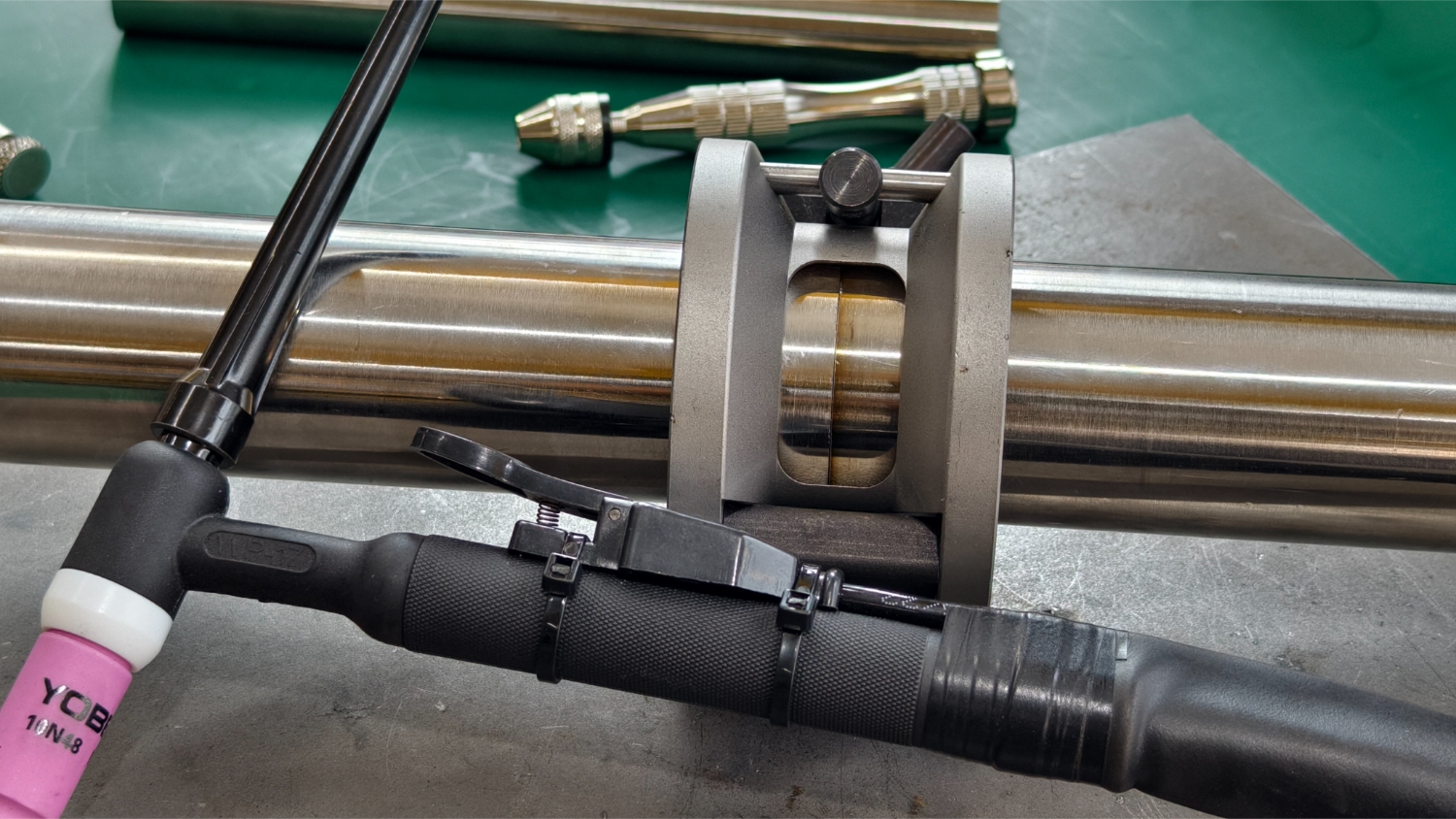

1. Planetary pipe cutting machine for precise blanking

The NODHA planetary pipe cutting machine utilizes a planetary cutter design with a circular feed. For pipes up to Ø50.8 mm, the machine directly clamps the pipe. The chipless cutting mode ensures a smooth end face with no heat-affected zone, burrs, or deformation, allowing for direct processing to the next step.

2. Beveling machine for welding

The NODHA pipe beveling machine is used to bevel the cut end of the pipe, achieving a high-quality surface finish with no oxidation residue, meeting the requirements of argon arc welding.

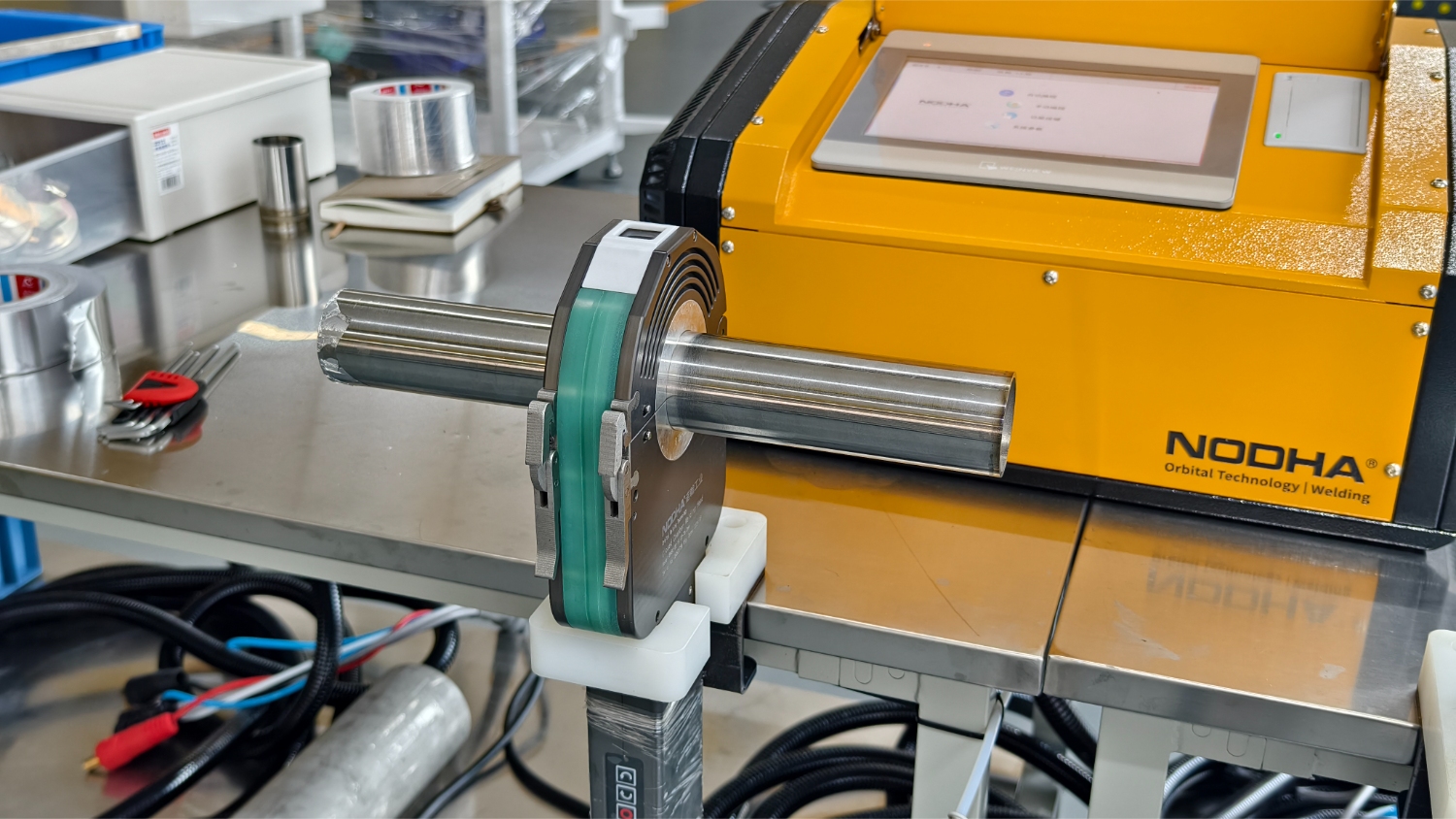

3. BH80 welding equipment completes welding

As the core equipment for this process, the BH80 boasts numerous technological highlights, including automatic programming and parameter matching. Using a P200 power supply with a built-in database, the system automatically generates welding parameters, including the current curve, wire feed speed, and gas advance/delay times, upon inputting the pipe material (stainless steel) and wall thickness (2.9 mm). An argon shielding system, with an outer gas hood covering the weld area and an internal gas inflator, ensures a uniform silver-white backside finish and prevents oxidation. Human-machine interaction simplifies operation; the operator simply clamps and aligns the pipe, selects a preset material-thickness parameter set, and starts welding. The equipment automatically completes arc quenching and gas delay shutoff.

III. On-site Implementation Results

1. Efficiency Improvement

The entire process, encompassing cutting, beveling, and welding, is shortened. The BH80 welding phase, including clamping and ventilation testing, takes only three minutes.

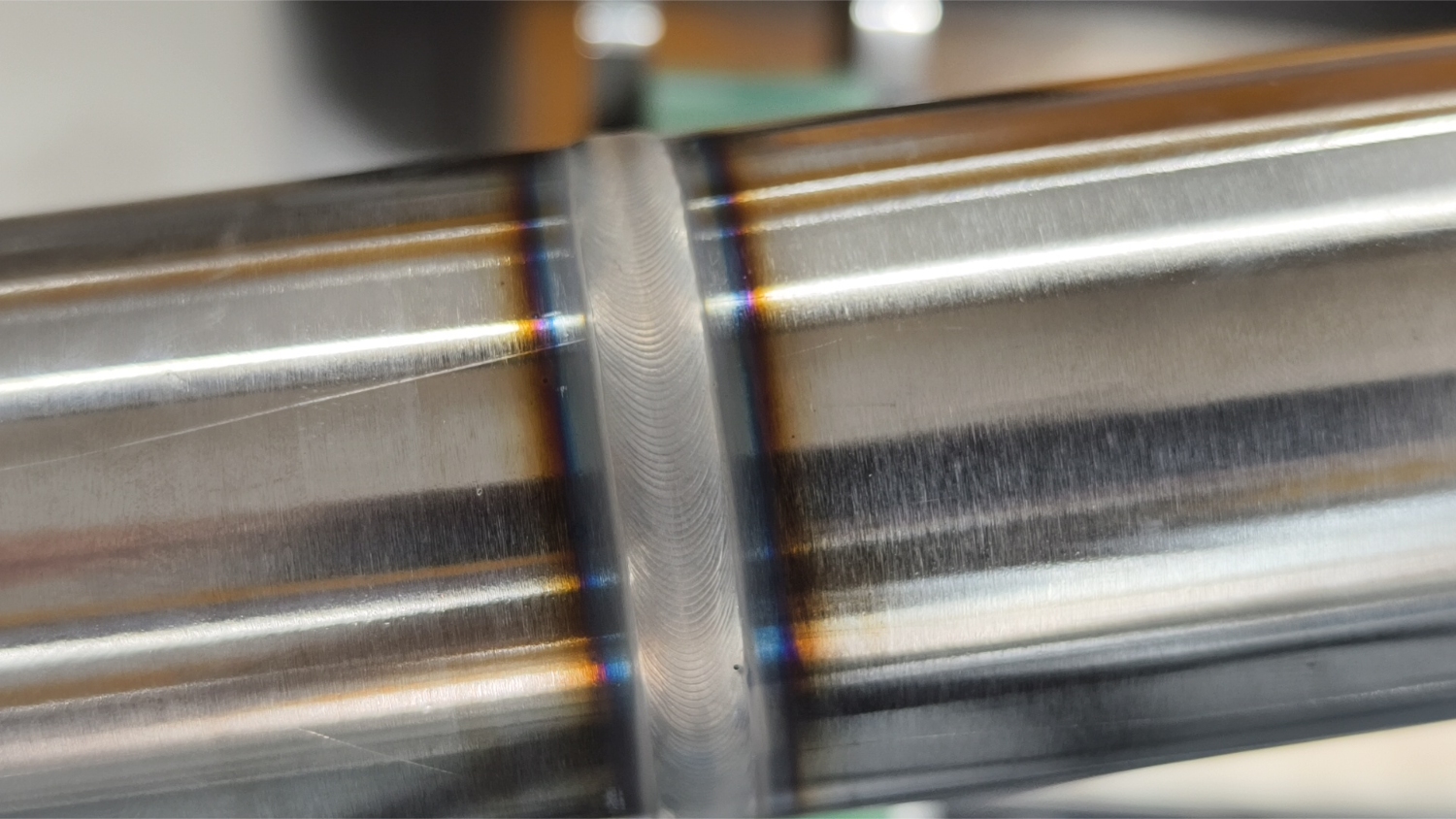

2. Process Quality

The weld seam's internal and external surfaces are uniform, free of defects such as dents and lack of fusion.

The argon shielding is excellent, resulting in a silvery-white weld with no oxidation stain.

3. Operational Ease and Safety

Both the planetary pipe cutting machine and beveling machine utilize a quick-fixture design, enabling changeovers in less than a minute.

The BH80 requires no programming experience, allowing an average worker to master the entire process in under two hours.

The entire line features electrical isolation and mechanical protection, ensuring spark-free operation and no high-noise operating points.