Home > Application > On Site Machining Equipment > On-site blind flange sealing surface machining solutions

Home > Application > On Site Machining Equipment > On-site blind flange sealing surface machining solutions We were very pleased to meet with BOKHAR of Iran.

We have had several successful cooperations before.

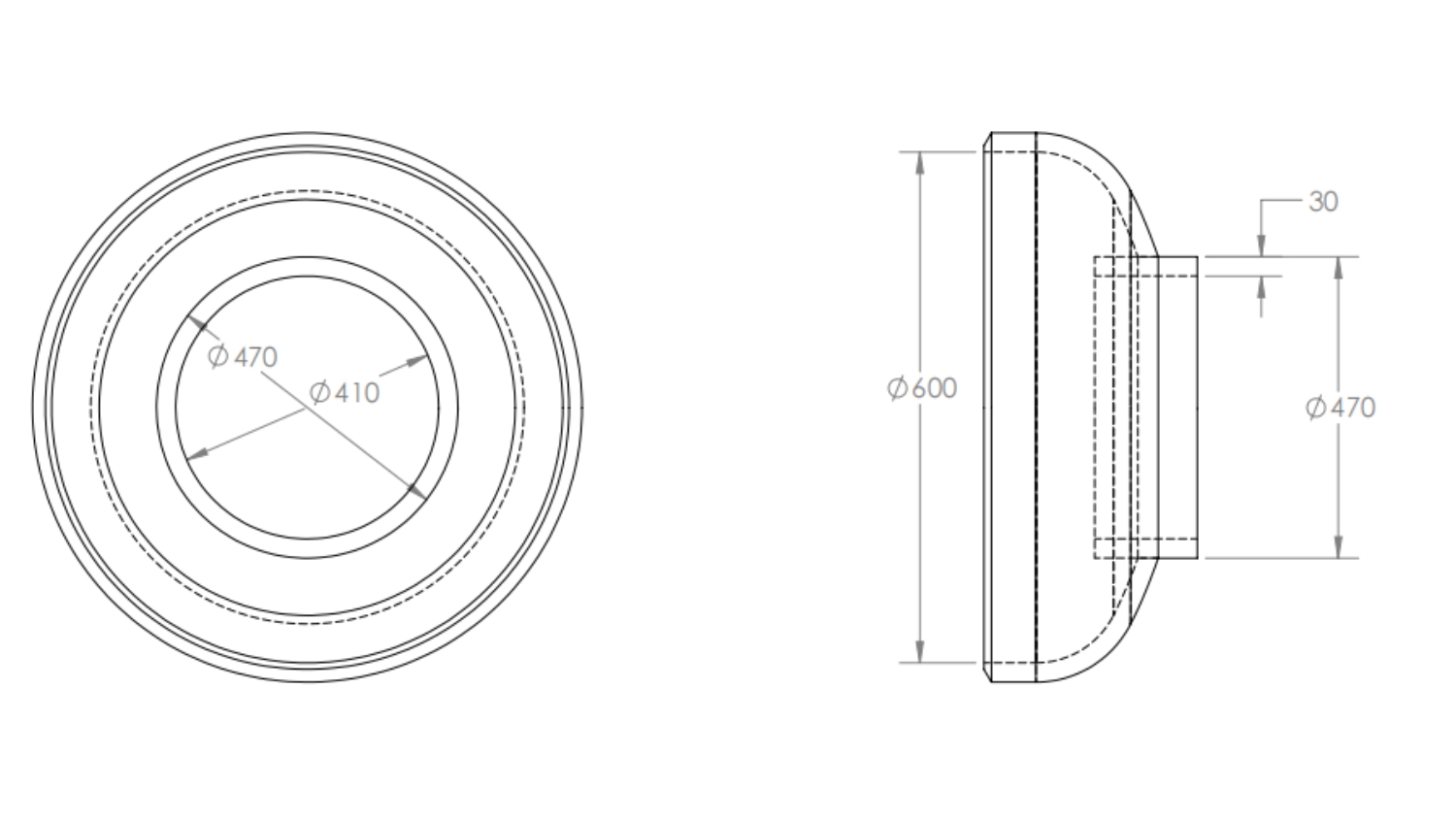

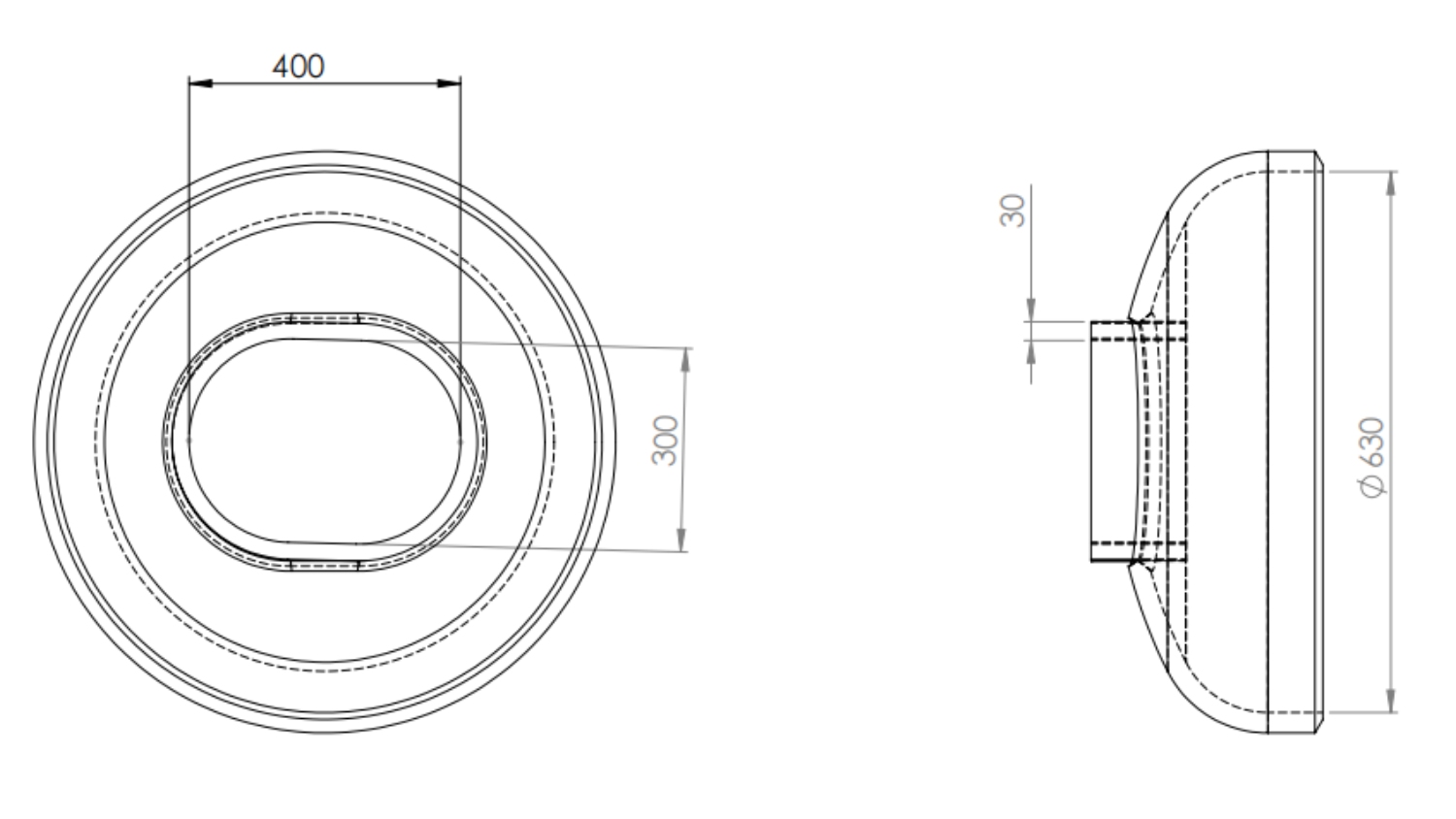

Mr. Fouladi's visiting was primarily to discuss on-site flange facing equipment. One particular application involved machining the sealing surface of a pressure vessel manhole cover: processing a blind plate in a confined space.

First, the machine's dimensions required access the manhole to enter the pressure vessel; second, its ability to be mounted on the blind plate; and finally, the required rotational diameter of the flange facer to operate within the confined space.

We recommended using a manual flange facer or the new pneumatically driven FI610P flange repair machine, which with a minimum rotation of 515mm only. It not only allows for smooth access through the manhole, but also can rotate within confined spaces and it is pneumatically driven. For mounting on the blind plate, we recommended welding. Mr. Fouladi, a highly experienced engineer, agreed with our proposal and praised our extensive industry experience.

We also discussed heat exchanger sealing surface machining. We showed Mr. Fouladi a recent job we had completed, facing the front of a heat exchanger's sealing surface and the back facing of the tubesheet. Through the video presentation, Mr. Fouladi expressed strong interest in our 3000mm on-site flange machining equipment, which includes the tube sheet mounting backing plate, backing facing tool holder, and all the necessary equipment. We agreed to provide a quote for this equipment once the heat exchanger dimensions are finalized.

On-site video:

1.Heat exchanger front-facing: This is a standard process for machining the external sealing surface of the flange. This surface is the critical interface between the heat exchanger and external piping or other equipment. It will have sealing grooves (such as convex, concave, or tongue-and-groove RTJ surfaces). This process creates a perfect sealing surface to ensure a leak-free connection with the tube sheet or header.

Heat exchanger front-facing: https://www.youtube.com/shorts/XVy3tLiFKQQ

2.Heat exchanger back-facing: This is a process for milling the inner end face of the flange after machining the sealing surface. This surface is welded or butted to the heat exchanger shell. It has a large hole in the center for tube bundle installation and removal. Maintaining perpendicularity between the inner end face of the flange and the shell bore provides a clear path for smooth tube bundle assembly.

Heat exchanger back-facing: https://www.youtube.com/shorts/p3wayCx4T_o

During the visit, we also introduced our stainless steel pipe cutting machines and tube sheet welding machines. Since BOKHAR manufactures petroleum and petrochemical equipment, they expressed strong interest.