The Korean customer took time out of their busy schedule to visit NODHA's new factory for an evening tour and exchange ideas. Despite the tight schedule, the entire reception was efficient and smooth, and both parties engaged in in-depth technical discussions and cooperation in a cordial and friendly atmosphere.

The staff provided the Korean customer with a detailed introduction to NODHA's latest equipment and application cases in pipe and tube-to-tube welding. The customer expressed strong interest in NODHA's products and raised questions regarding technical details, performance parameters, and practical application scenarios, which the technical team provided expert answers to.

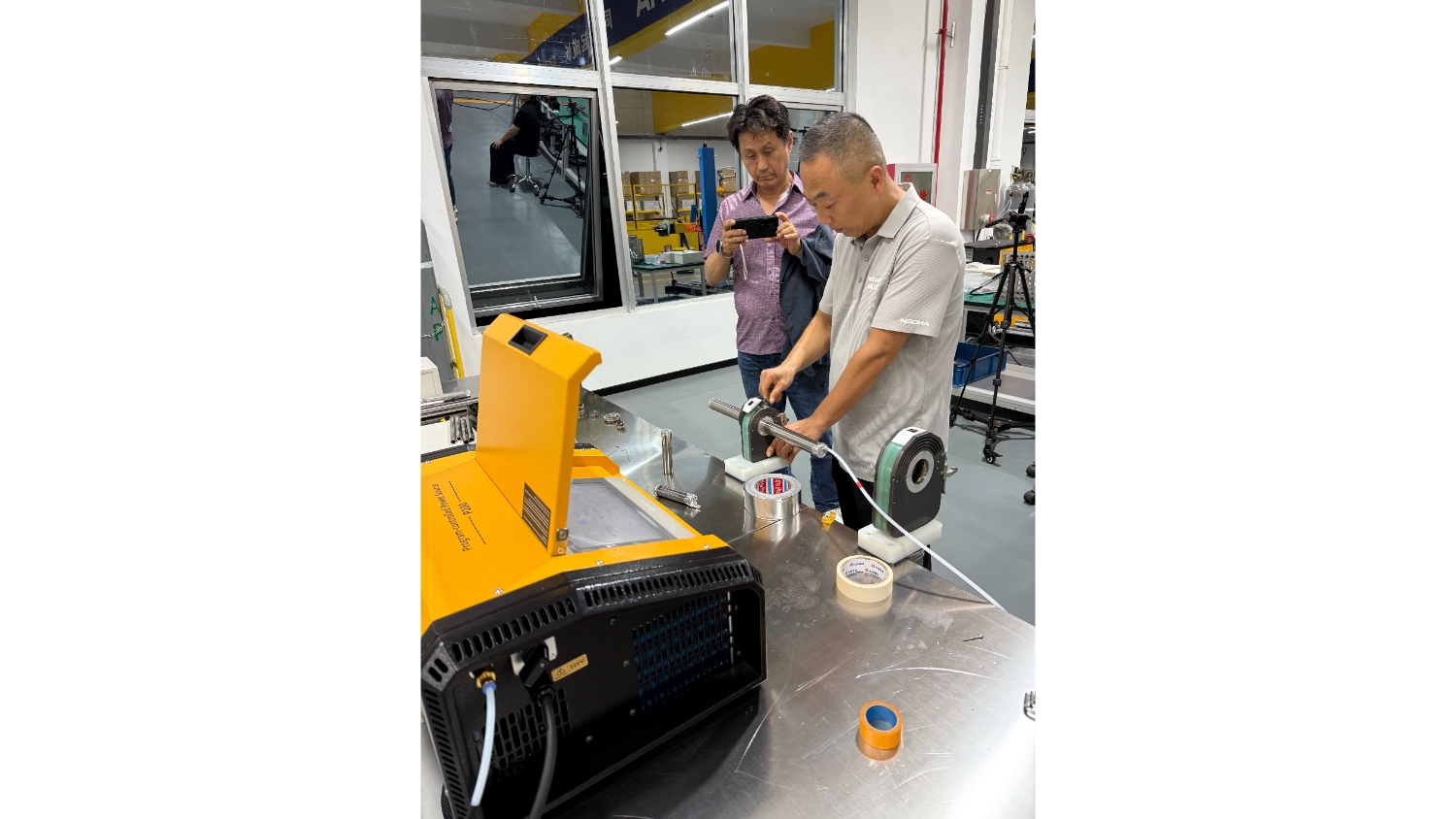

The customer then moved to the welding demonstration area, where they observed NODHA's BH40 and BH80 pipe-to-pipe welders, as well as the TS80 tube-to-sheet welder, in action. The customer was deeply impressed by the high penetration stability and weld quality of the BH series equipment during pipe butt welding. The TS80 also received high praise for its flexible positioning capabilities and multi-parameter adaptive features during simulated tube-to-sheet welding.

At the end, both sides took a group photo, ending this efficient and pleasant evening meeting.