Thin-walled tube welding has always been a challenging task for manufacturers across industries. The combination of small diameters, delicate wall thickness, and high precision requirements makes traditional welding methods inefficient, error-prone, and costly. Enter the orbital welding machine—a technology that has fundamentally transformed the way thin-walled tubes are welded, offering unmatched precision, efficiency, and reliability.

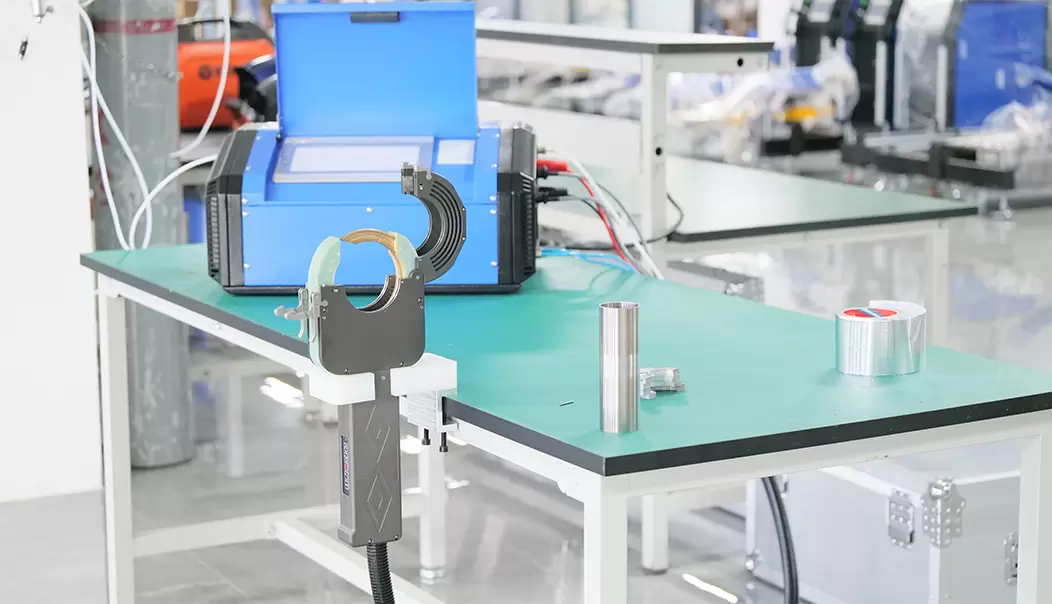

Orbital welding is a specialized process where the welding arc rotates mechanically around a stationary workpiece, typically a pipe or tube. Unlike manual welding, the movement of the welding arc is controlled by a pre-programmed machine, which allows for consistent, repeatable welds with minimal human intervention. The core of this system is the orbital welding power source, such as the advanced P200 digital model, which provides precise control over current, rotation speed, and shielding gas, ensuring optimal weld quality.

Thin-walled tubes, commonly used in industries such as chemical processing, pharmaceuticals, food production, and semiconductors, present several unique challenges:

Wall Thickness Sensitivity: Thin walls are prone to burn-through, warping, and deformation under excessive heat. Manual welding methods often lack the precision needed to protect these delicate tubes.

Consistency Issues: Achieving uniform welds in all positions is difficult manually, leading to inconsistent quality and increased rejection rates.

Time-Consuming Processes: Manual welding of thin-walled tubes requires highly skilled operators and slow, careful execution, which can slow down production lines.

Orbital welding machines directly address these challenges through automation, precise parameter control, and intelligent programming.

One of the most significant advantages of orbital welding machines is unparalleled precision. The P200 digital orbital welding power source, for instance, allows for exact control over welding current, rotation speed, and shielding gas flow. These parameters can be stored and recalled through a digital interface, creating a library of welding programs for different tube diameters and wall thicknesses. This ensures consistent welds every time, reducing human error and minimizing waste.

Traditional welding often requires operators to manually calculate settings based on tube diameter, wall thickness, and material type. Modern orbital welding machines automate this process. Using built-in parameter libraries, the machine can automatically calculate optimal welding parameters, including heat input, travel speed, and gas flow. This not only saves time but also allows operators with less experience to achieve professional-grade welds.

Thin-walled tubes are often installed in complex geometries, requiring welding in horizontal, vertical, or even overhead positions. Orbital welding machines are designed for all-position welding, allowing the arc to rotate around the tube seamlessly. This eliminates the need for multiple setups and repositioning, greatly improving production efficiency.

Even with precise programming, certain welds may require fine-tuning. Advanced orbital welding machines provide real-time control over current and speed, allowing operators to make adjustments during the welding process. This flexibility is crucial when welding delicate materials or meeting strict industry standards.

Quality assurance is critical in industries such as pharmaceuticals and semiconductor manufacturing, where weld defects can compromise safety and performance. Orbital welding machines are equipped with fault detection systems that monitor water flow, shielding gas, and electrical parameters. When a fault occurs, the system immediately alerts the operator and displays the cause, ensuring rapid resolution and reducing downtime.

Modern orbital welding machines, like the P200, also support software upgrades, U-disk upgrades, and offline programming. This means operators can prepare welding programs in advance, optimize parameters remotely, and update machine software without halting production. Such features make orbital welding machines highly adaptable to evolving production needs.

Orbital welding machines are widely used in industries where thin-walled tubes are prevalent:

Chemical Processing: High-purity piping systems require consistent, defect-free welds to prevent leaks and contamination. Orbital welding ensures repeatable quality even in long pipeline networks.

Pharmaceuticals: Sterile manufacturing environments demand precise welds with smooth internal surfaces to meet strict hygiene standards.

Food and Beverage: Tubing in production lines must be welded without crevices to avoid bacterial buildup. Orbital welding provides smooth, high-quality welds.

Semiconductors: Extremely thin and small-diameter tubes in semiconductor equipment require precision welding to maintain vacuum integrity and prevent contamination.

Heat Exchangers: Tubes with thin walls require high-speed, precise welding to ensure thermal efficiency and structural integrity.

| Feature | Orbital Welding Machine | Manual/Traditional Welding |

|---|---|---|

| Precision | High, controlled digitally | Variable, depends on operator skill |

| Repeatability | Excellent, consistent welds | Poor, high variability |

| Efficiency | Automated, faster production | Slow, labor-intensive |

| Fault Detection | Real-time, integrated | Minimal, requires inspection |

| Safety | Reduced operator exposure | Higher exposure to fumes and heat |

As industries demand higher precision and efficiency, orbital welding technology continues to evolve. Future trends include:

Artificial Intelligence Integration: AI-driven welding programs can adapt parameters in real-time based on tube conditions.

Advanced Data Analytics: Collecting welding data for quality tracking and predictive maintenance.

Robotics Integration: Fully automated robotic orbital welding systems for complex assemblies.

Sustainable Welding Practices: Reduced energy consumption and improved resource efficiency.

The orbital welding machine has truly revolutionized thin-walled tube welding. By combining automation, precision, real-time adjustments, and intelligent programming, it addresses the limitations of traditional welding methods. Industries such as chemical processing, pharmaceuticals, food production, and semiconductors now rely on orbital welding machines for high-quality, efficient, and repeatable welds.

For manufacturers looking to improve productivity, reduce errors, and ensure consistent weld quality, investing in an orbital welding machine is no longer an option—it is a necessity. With ongoing advancements in digital controls, AI, and robotics, orbital welding technology is poised to remain at the forefront of industrial welding innovation.