As food processing equipment continues to improve its hygiene standards and precision requirements, food-grade stainless steel welding has become a key focus in the industry. Traditional manual welding methods are not only inefficient, but also significantly impact weld quality due to operator skill, making them unable to meet the high-precision, pollution-free welding requirements of modern food processing equipment. Against this backdrop, orbital welding machines, as automated, high-precision welding equipment, have been widely used in food-grade stainless steel welding, becoming a crucial tool for improving production efficiency and product quality.

Food-grade stainless steel welding differs from ordinary stainless steel welding in its key features:

High Hygiene Standards: Food-grade stainless steel weld surfaces must be smooth and flat, free of slag, weld bumps, and burrs to prevent bacterial growth. Welds must be easy to clean and meet national and international food hygiene standards.

High Corrosion Resistance: During food processing, equipment often comes into contact with acidic and alkaline substances. Improper weld treatment can lead to corrosion, shortening the weld life.

High Precision and Consistency: Welding areas on equipment, such as pipes, containers, and storage tanks, require stringent dimensional accuracy. Uneven or distorted welds can compromise the overall structure and sealing performance. Traditional manual welding struggles to simultaneously meet all three of these requirements. This limitation is particularly evident in large-scale production or high-precision pipe welding, where manual operation is particularly challenging.

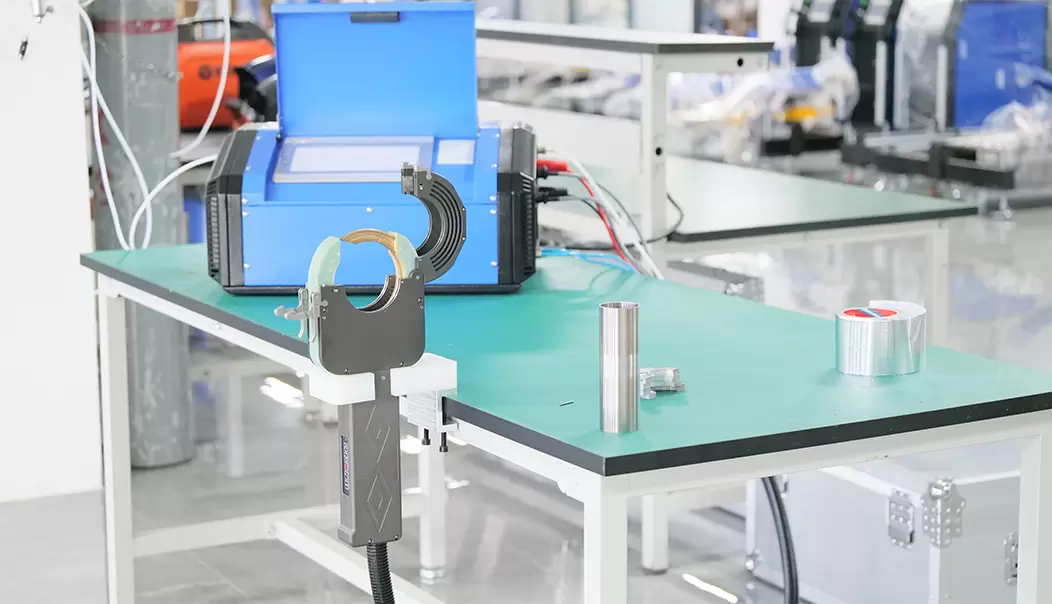

Orbital welding machines use a welding torch that automatically moves along a track. They are commonly used for welding long straight pipes, curved pipes, and irregular structures. Their advantages in welding food-grade stainless steel are primarily reflected in the following aspects:

High-precision welding: Orbital welding machines use program-controlled welding torch trajectory to ensure weld stability and consistency, reduce weld deviation, and meet the precision requirements of food-grade equipment.

High welding speed: Automatic track movement combined with programmed welding paths significantly improves welding efficiency. This efficiency advantage is particularly evident in welding batches of pipes or tanks on production lines.

Smooth and beautiful welds: Automated control ensures uniform wire feeding, sufficient weld fusion, and a smooth, flat weld surface with no noticeable spatter, reducing subsequent grinding and cleaning.

Reduced human error: Manual welding is susceptible to operator skill and fatigue, leading to fluctuations in weld quality. Orbital welding machines use programmed operation to ensure consistent welds and reduce rework. Adaptable for welding complex structures: Orbital welding machines can achieve high flexibility by adjusting the orbital shape or using a rotating device to weld complex bends, container bottoms, or multiple pipe sections.

Orbital welding machines are primarily used in the following areas of food processing equipment manufacturing:

3.1 Pipe Welding

Food-grade stainless steel pipes are often used to transport liquid or powdered food ingredients, requiring extremely high welding precision. Orbital welding machines automatically move along the pipes, achieving high-precision welding of both straight and curved pipes. Compared to manual welding, welds are more uniform, with less internal spatter, meeting hygiene standards.

3.2 Tank and Container Welding

Food equipment such as storage tanks, mixing tanks, and fermentation tanks require strict weld sealing and a smooth, even surface. With its equipped rotary table and multi-axis control, orbital welding machines enable fully automated welding of the bottoms and sidewalls of large containers, ensuring weld sealing and a beautiful surface.

3.3 Elbow and Special-Shaped Part Welding

Food processing equipment often contains a large number of special-shaped parts such as elbows and tees. Traditional manual welding is not only inefficient but also difficult to ensure weld consistency. Orbital welding machines, through customizable tracks and program control, can weld complex stainless steel parts, improving production efficiency and weld quality.

3.4 Large-Scale Assembly Line Welding

In large-scale food production lines, automated assembly line equipment is numerous, requiring efficient batch welding. Orbital welding machines can be combined with robots or automated conveyor systems to achieve automated batch welding of stainless steel equipment, reducing labor and improving production efficiency.

To ensure the quality of food-grade stainless steel welds, the following points should be noted when using orbital welding machines:

Welding Parameter Optimization: Parameters such as welding current, voltage, welding speed, and wire diameter should be optimized based on the thickness of the stainless steel, welding position, and weld type to ensure smooth welds with acceptable strength.

Track Accuracy and Installation Stability: The track of the orbital welding machine must be level and stable. Track deviation directly affects weld quality. Regular inspection of track straightness and machine operation stability is crucial.

Welding Environment Control: Welding food-grade stainless steel requires a clean environment to prevent contamination of the weld surface by impurities such as dust and oil. The welding area must also be ventilated to prevent the accumulation of welding fumes.

Post-welding Treatment: Although orbital welding machines produce smooth weld surfaces, post-treatment procedures such as polishing, pickling, and passivation are still required according to standards to ensure a smooth, contamination-free weld and meet food hygiene requirements.

Operator Training: Although orbital welding machines are highly automated, operators still need to master equipment program settings, welding parameter adjustments, and process monitoring to ensure efficient and stable operation.

The use of orbital welding machines in welding food-grade stainless steel not only improves welding accuracy and production efficiency, but also effectively reduces labor costs and welding defect rates. With the continuous development of automation technology and intelligent equipment, orbital welding machines will become a vital tool for food processing equipment manufacturers to improve product quality and meet high hygiene standards. Selecting the right orbital welding machine and using it effectively will help companies gain an advantage in the fiercely competitive market and achieve efficient, precise, and hygienic production goals.

As a professional orbital welding machine distributor, NODHA is committed to providing efficient and reliable welding equipment and technical support to the food processing, pharmaceutical, chemical, and high-precision manufacturing industries. The company boasts an advanced automated orbital welding system capable of meeting the stringent weld seam accuracy, surface finish, and sanitation requirements of food-grade stainless steel. NODHA also provides a one-stop service from equipment selection and installation to operator training and after-sales maintenance, ensuring high efficiency, minimal rework, and superior welding results for customers throughout their production processes.