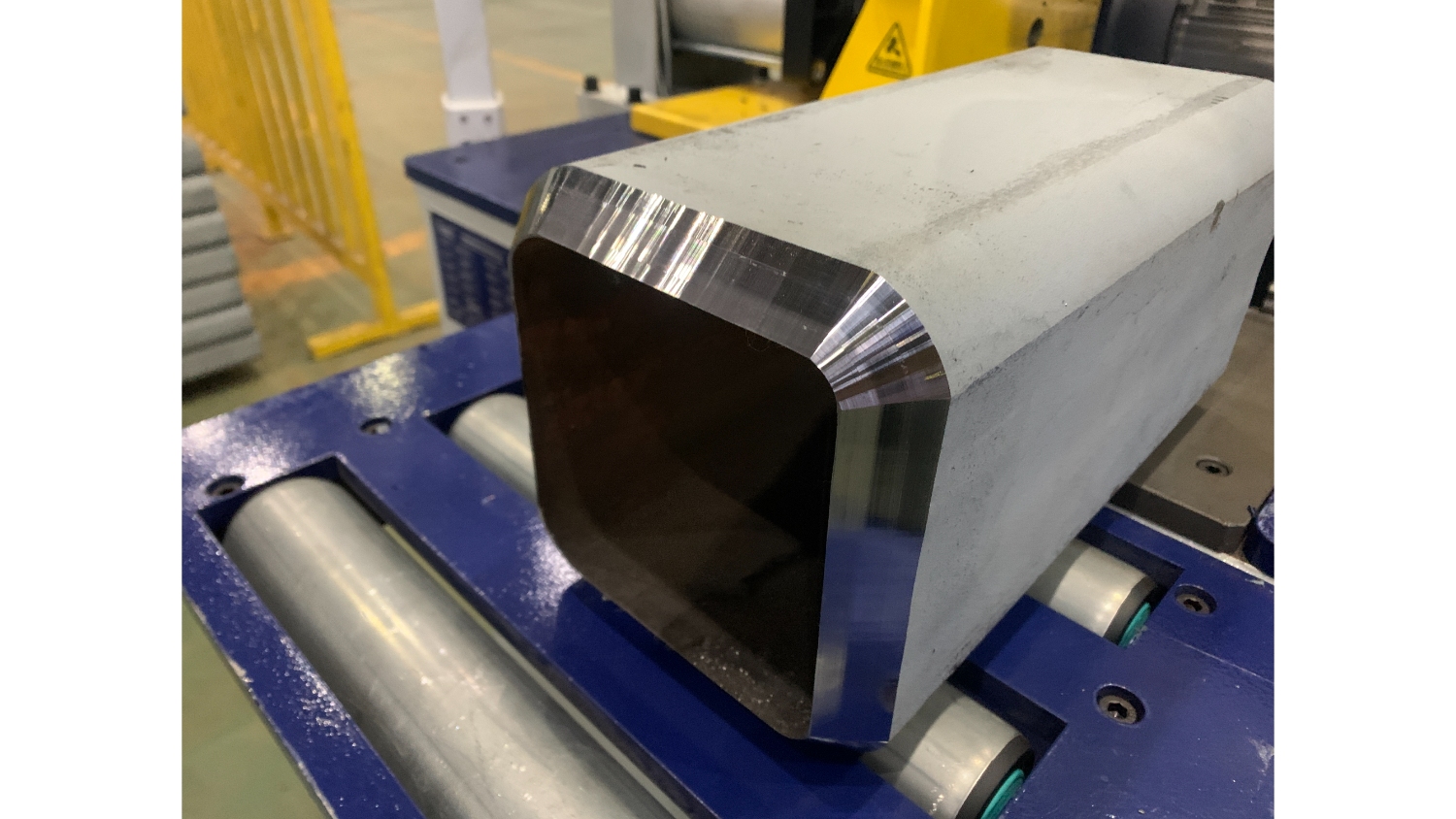

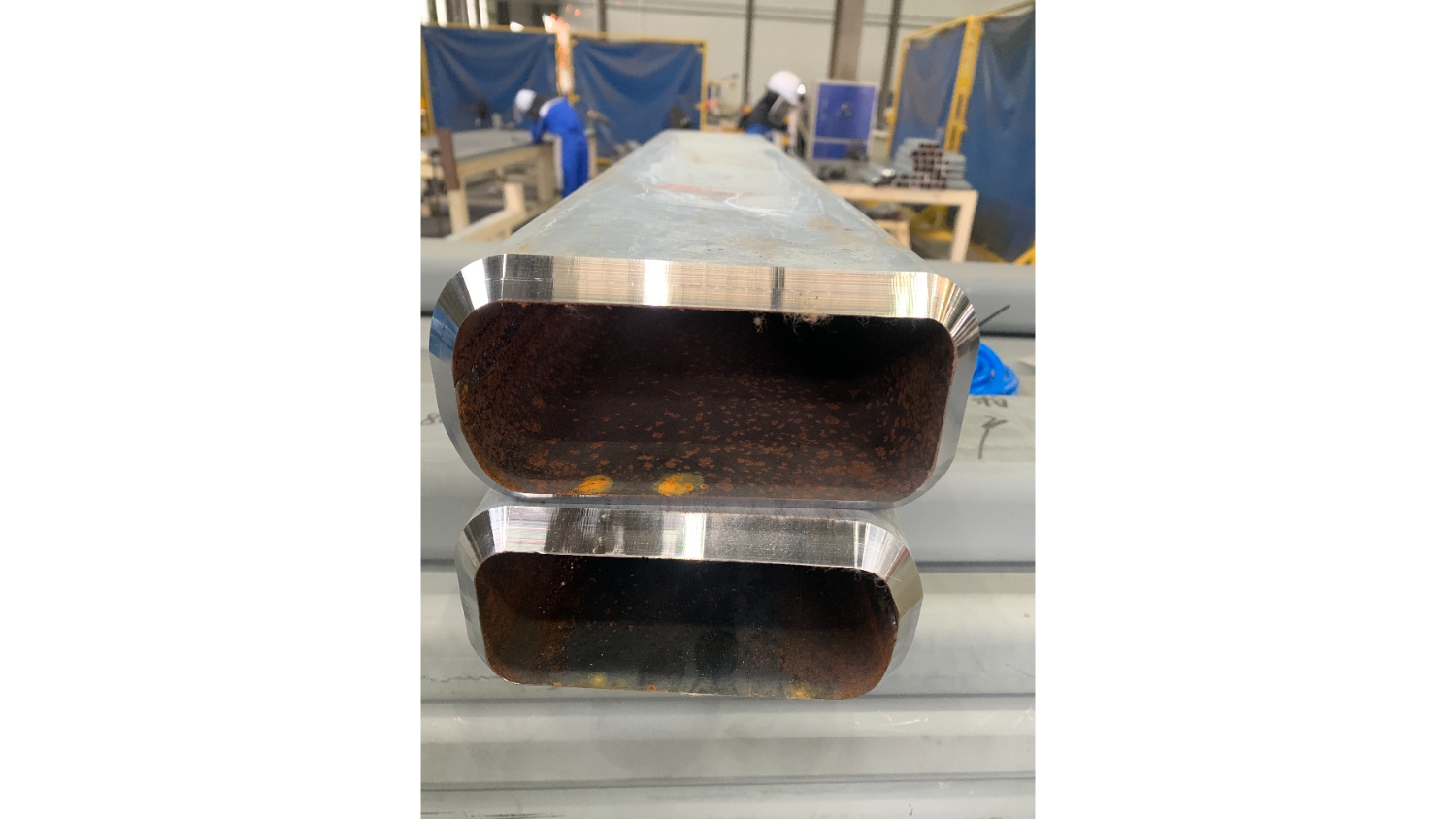

NODHA's partner, GIRET, successfully completed a square and rectangular tube beveling project for China International Marine Containers (CIMC Containers). The core equipment used in this project was the GPM-ST300 CNC dual-purpose automatic square and round tube beveling machine, which efficiently and accurately bevels square and rectangular tubes, significantly improving the quality and efficiency of weld preparation for key structural components.

Beveling is a crucial pre-welding step, and its quality directly impacts the joint strength and safety of structural components. In container manufacturing, beveling square and rectangular tubes is a critical process, directly impacting the joint strength and sealing performance of the container structure. Therefore, stringent requirements for machining accuracy and efficiency are crucial. In this operation, GIRET's GPM-ST300 equipment, with its stable performance, demonstrated its high adaptability and stability to CIMC's square and rectangular tube beveling requirements. This machine integrates the functions of beveling both square and round tubes, utilizing a CNC system for automated processing. This not only ensures consistent beveling angles and dimensions, but also significantly reduces manual labor and error rates, effectively guaranteeing product quality and reliability.

GPM-ST300 CNC Square Tube Beveling Machine Overview: This machine is designed specifically for beveling pipes and square tubes. It can be used for both without the need for component replacement, providing dual-purpose functionality and reducing procurement costs. It offers high beveling efficiency and surface finishes of up to Ra3.2 to 6.3. This machine is primarily used for prefabricated beveling processes in pipe processing workshops. Its operation is simple and safe, and can be easily operated by a single operator.

CIMC Group is highly selective in its selection of production equipment and supply chain partners. Its choice of GIRET stems from its strong recognition of their advanced equipment performance and professional technical service capabilities. The smooth implementation and high degree of completion of this project fully demonstrate the deep technical expertise and practical capabilities of NODHA's partner, GIRET, in the field of specialized industrial processing equipment.